Omatilasi abanethezekile banomphumela wokuthuthukisa ikhwalithi yokulala. Omatilasi benziwa ngezinto ezihlukahlukene, njengesundu, irabha, iziphethu, i-latex, njll. Kuye ngezinto zabo, bafanele amaqembu ahlukene abantu. Lapho abahloli behlola omatilasi abahlukahlukene, kufanele bahlole ukuthi yiziphi izici futhi banake ngokukhethekile noma yimaphi amaphutha. Umhleli ukufingqile okuqukethwe kokuhlolwa komatilasi futhi ukuthole kuwusizo futhi kungaqoqwa!

Izindinganiso zokuhlolwa komkhiqizo nokupakishwa 1. Umkhiqizo

1) akumele kube nezinkinga zokuphepha ngesikhathi sokusetshenziswa

I-2) Ukubukeka kwenqubo kumele kungabi nomonakalo, imihuzuko, imifantu, njll.

3) Kufanele ihambisane nemithetho neziqondiso zezwe okuyiwa kulo kanye nezidingo zamakhasimende

4) Isakhiwo somkhiqizo, ukubukeka, inqubo, nezinto zokwakha kumele zihlangabezane nezidingo zamakhasimende kanye namasampula eqoqo

5) Umkhiqizo kufanele uhlangabezane nezidingo zekhasimende noma imisebenzi efanayo namasampula eqoqo

6) Ukuhlonza ilebula kufanele kucace futhi kuhambisane nezidingo zomthetho nezokulawula

I-1) Iphakheji kufanele ifaneleke futhi iqine ngokwanele ukuze kuqinisekiswe ukwethembeka kwenqubo yokuthutha umkhiqizo.

2) Izinto zokupakisha kumele zikwazi ukuvikela ukuthuthwa komkhiqizo.

3) Izimpawu zokuthumela, amabhakhodi, namalebula kufanele ahlangabezane nezidingo zekhasimende noma amasampula eqoqo.

4) Izinto zokupakisha kufanele zihlangabezane nezidingo zekhasimende noma amasampula eqoqo.

5) Umbhalo ochazayo, imiyalelo, nezixwayiso zelebula ezihlobene kufanele ziphrintwe ngokucacile ngolimi lwezwe okuyiwa kulo.

6) Incazelo yemiyalelo kumele ihambisane nomkhiqizo kanye nemisebenzi efanele

1) Amazinga Okuhlola Asebenzayo: ISO 2859/BS 6001/ANSI/ASQ-Z 1.4 Uhlelo Olulodwa Lwesampula, Ukuhlola Okuvamile.

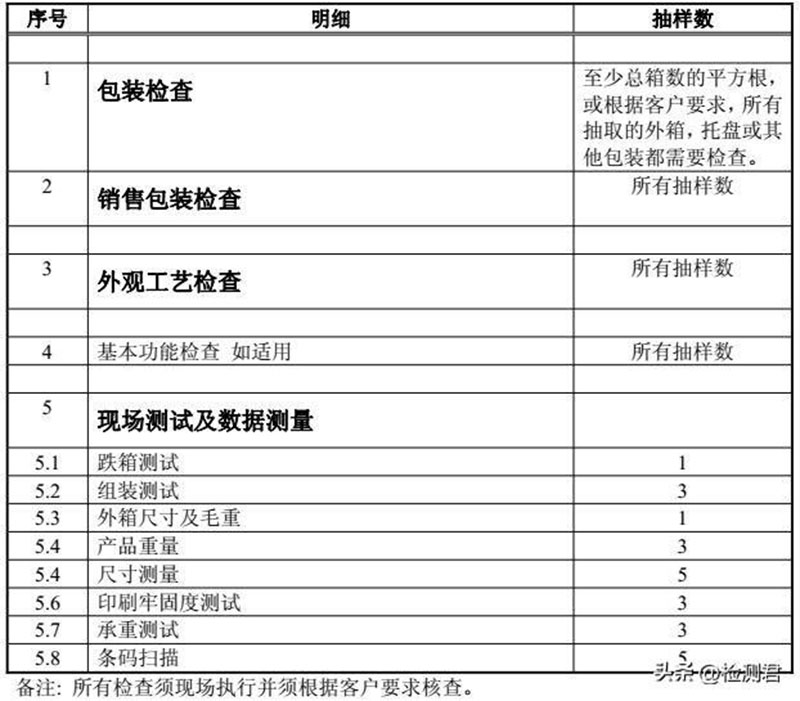

2) Izinga lamasampula: Sicela ubhekisele ezinombolweni zamasampula kuthebula elilandelayo

3) Uma imikhiqizo eminingi ihlanganiswa ukuze ihlolwe, inombolo yesampula yomkhiqizo ngamunye inqunywa iphesenti yenani lomkhiqizo walo lonke iqoqo. Bala inombolo yesampula yalo mkhiqizo ngokulingana ngokusekelwe kumaphesenti okuhlala kuwo. Uma inombolo yesampula ebaliwe ingaphansi kuka-1, amasampula amabili azothathwa njengesampula yeqoqo lonke, noma isampula elilodwa lizothathwa njengokuhlolwa okukhethekile kwezinga lesampula.

3) Uma imikhiqizo eminingi ihlanganiswa ukuze ihlolwe, inombolo yesampula yomkhiqizo ngamunye inqunywa iphesenti yenani lomkhiqizo walo lonke iqoqo. Bala inombolo yesampula yalo mkhiqizo ngokulingana ngokusekelwe kumaphesenti okuhlala kuwo. Uma inombolo yesampula ebaliwe ingaphansi kuka-1, amasampula amabili azothathwa njengesampula yeqoqo lonke, noma isampula elilodwa lizothathwa njengokuhlolwa okukhethekile kwezinga lesampula.

4) Izinga elamukelekayo lekhwalithi ye-AQL: Akukho ukukhubazeka okungathi sína okuvunyelwe Isici esibucayi I-AQL xx Iphutha elikhulu I-AQL xx Indinganiso yokukhubazeka okuncane Qaphela: “xx” imele izinga lekhwalithi elamukelekayo elidingwa ikhasimende.

5) Inani lamasampula amasampula akhethekile noma angashintshi, Ukungahambisani nokungahambisani akuvunyelwe.

6) Imithetho evamile yokuhlukaniswa kwamaphutha: (1) Isici Esibucayi: Amaphutha abangela ukulimala komuntu siqu noma izici ezingaphephile lapho kusetshenziswa noma kugcinwa imikhiqizo, noma amaphutha aphula imithetho nezimiso ezifanele. (2) Ukukhubazeka Okukhulu Ukukhubazeka kokusebenza kuthinta ukusetshenziswa noma ukuphila, noma ukonakala okusobala okubonakalayo kuthinta inani lokuthengisa lomkhiqizo. (3) Amaphutha amancane amaphutha angathinti ukusetshenziswa komkhiqizo futhi akuhlobene nenani lokuthengisa lomkhiqizo.

7) Imithetho yokuhlolwa okungahleliwe: (1) Ukuhlolwa kokugcina kudinga ukuthi okungenani i-100% yemikhiqizo ikhiqizwe futhi yapakishwa ukuze ithengiswe, futhi okungenani ama-80% emikhiqizo apakishwe emabhokisini angaphandle. Ngaphandle kwezimfuneko ezikhethekile ezivela kumakhasimende. (2) Uma kutholakala amaphutha amaningi kusampula, isici esibi kakhulu kufanele sibhalwe njengesisekelo sokwahlulela. Wonke amaphutha kufanele ashintshwe noma alungiswe. Uma kutholakala amaphutha amakhulu, iqoqo lonke kufanele linqatshwe futhi ikhasimende kufanele linqume ukuthi liyazikhulula yini izimpahla.

4. Inqubo yokuhlola nokuhlukaniswa kwamaphutha

Imininingwane yezinombolo ze-serial, ukuhlukaniswa kokukhubazeka I-CriticalMajorMinor1) Ukuhlolwa kokupakisha, ukuvuleka kwesikhwama sepulasitiki>19cm noma indawo>10x9cm, azikho izimpawu eziyisixwayiso zokuminyaniseka eziphrintiwe, izimpawu eziyisixwayiso zokuphepha ezingu-X azikho noma aziphrintwe kahle, izimpawu ezichazayo ezingu-X azikho noma aziphrintwe kahle, ulimi X lwezwe okuyiwa kulo alikho. , ukuhlonza imvelaphi engu-X abukho, igama elingu-X lokungenisa ezweni nekheli alikho noma aliphrintwe kahle, ukumaka u-X noma inkinga yomsebenzi wobuciko: akukho okuqukethwe, ifomethi engalungile, Imiphetho eyingozi namaphuzu acijile kuphakheji, njengo-X, awonakele, aqhekekile, akhubazekile, futhi angcolile, izinto ezingalungile ezingu-XX noma izinto zokupakisha ezingalungile njengamabala noma umswakama X ukupakisha okuxekethile X ukuphrinta okungacacile X ukupakishwa kwephalethi akukho. ukuhlangabezana nezidingo zekhasimende X ukupakisha ngokhuni akuhlangabezani nezidingo zokulawula X2) iphutha losayizi wokuhlolwa kokuthengisa X iphutha lokupakisha X alikho i-desiccant X engalungile yokulenga ubakaki X abakaki abalengayo abalahlekile X ibhande elilahlekile noma ezinye izingxenye X izesekeli ezingekho X isikhwama sepulasitiki esilimele X iphutha lesikhwama sepulasitiki X iphunga X isikhunta X esimanzi XX iziqubulo zesexwayiso zokuphepha ezingekho noma eziphrintiwe Iziqubulo ezichazayo ezingu-X ezingekho noma ezingafundeki

3) Ukubukeka kanye nokuhlolwa kwenqubo

Ikhoyili esengozini yokulimala X inaliti ecijile noma insimbi yangaphandle X izingxenye ezincane emikhiqizweni yezingane X iphunga elingavamile X izinambuzane eziphilayo X amabala egazi X ulahlekile ulimi olusemthethweni lwezwe X elingekho indawo yendabuko X intambo ephukile X intambo ephukile X iyazulazula Intambo yombala engu-XX XX iyaphotha XX intambo yesisu esikhulu XX ifindo likakotini XX inaliti ephindwe kabili X imbobo ephukile X umonakalo wendwangu X ibala XX ibala lamafutha XX ibala lamanzi XX umehluko wombala XX uphawu lwepensela XX uphawu lweglue XX inhloko yentambo XX indaba yangaphandle XX umehluko wombala X uyaphela X uku-ayina okungalungile XX ukucindezelwa ukuwohloka X ukuqina kokucindezela X crease XX crease XX unqenqema oluqinile XX Intambo Ephukile X Umgodi Owayo X Intambo Yokugxuma XX Intambo Egoqayo XX Intambo Engalingani XX Engavamile Intambo XX Inalithi Yegagasi XX Ithunga Kalula X Inalithi Yokubuyisela Empofu X Ayikho Idethi X Ukungaboni ngaso linye Kosuku X Ukuthunga Okulahlekile X Ukungalungi kahle Kwe-Seam X Ukushuba Okukhululekile X Intambo Yokuthunga Okuxekethile X Intambo Yezino Lezino XX Intambo Eboshiwe XX Ukuqhuma Ukuqhuma X Intambo Eshwabene XX Umthungo Osontekile X Umthungo Oxekethile/Umphetho X Ukugoqa Umthungo X Ukungahambi kahle kokugoqeka komthungo I-X I-Seam Slip X I-Seam Misalignment X Ukungahambi kahle Kwe-Seam X Ukungaboni kahle Komthungo X Ukungaboni kahle Komthungo X Ukungalungi kahle Komthungo X Ukufekethiswa Okulahlekile X Ukufekethiswa Okungalungi X Ukufekethiswa Okuphukile Intambo Efekethisiwe X Ukungaqondani kahle Kwe-Embroidery Uchungechunge XX Ukuphrinta Okungalungile XX uphawu lokuphrinta XX ukususwa kokuphrinta XX kuyafiphala Iphutha le-XX lokuphrinta Iphutha lokuphrinta nge-electrolxx i-coach scratch XX ukungahambi kahle kwe-X I-Velcro ayifani X Ilebula le-Elevator alikho X Iphutha lemininingwane yelebula ye-Elevator iphutha lokuphrinta imininingwane yelebula ye-Elevator XX Ulwazi lwelebula le-Elevator luvinjiwe Ilebula le-XX Elevator alivikelekile XX ukungahambi kahle kwelebula le-XX ngaphambili nangemuva X ilebula esontiwe XX4) Uziphu wokuhlola osebenzayo, inkinobho, inkinobho emine, i-rivet , Ukungasebenzi kahle kwe-Velcro nezinye izingxenye X Umsebenzi uziphu ongalingani XX

5. Ukulinganiswa kwedatha nokuhlolwa kwendawoyokuhlolwa kwebhokisi lokudonsa le-ISTA IA. Uma kutholakala ukushiyeka kokuphepha nokusebenza noma ukonakala okubalulekile, yonke inqwaba yokuhlolwa kwenhlangano izonqatshwa. Umkhiqizo uzoqoqwa ngokulandela imiyalelo futhi uguqulelwe kuhlobo lombhede ohambisanayo ukuze kuqinisekiswe ukuthi izesekeli ziphelele, imiyalelo yomhlangano icacile, nomsebenzi womkhiqizo ngemva komhlangano usuqedile. Ubukhulu nesisindo seqoqo lonke lamabhokisi omsila kufanele kuhambisane nokuphrinta kwebhokisi langaphandle, nokubekezelela okungu-± 5%. Ukuhlolwa kwesisindo kuzosuselwa ezidingweni zekhasimende, futhi uma singekho isidingo, Chaza ukubekezelela okungu-± 3%. Yenqaba ukuhlolwa kosayizi wenqwaba. Ngokwezidingo zekhasimende, uma zingekho izidingo, qopha usayizi wangempela otholiwe. Yenqaba yonke inqwaba yokuphrinta ukuze kuhlolwe ukuqina. Sebenzisa izikhwama zepulasitiki ezingu-3M 600 ukuze uzihlole, futhi uma kukhona ithimba lokuphrinta. 1. Sebenzisa izikhwama zepulasitiki ezingu-3M ukuze unamathele kuphrinta bese ucindezela ngokuqinile amadigri angu-2.45 ukuze uklebhule itheyiphu. 3. Hlola ukuthi kukhona yini iqembu lokuphrinta kutheyiphu nokuphrinta. Yenqaba yonke inqwaba yokuhlolwa kwesisindo. Beka i-disc ethwala umthwalo (ububanzi be-100MM embuthanweni) phakathi futhi usebenzise amandla angu-1400N, Ngokuqhubekayo ngomzuzu ongu-1, umkhiqizo kufanele ungonakalisiwe, uqhekeke, futhi ukwazi ukusetshenziswa ngokujwayelekile njengoba kudingeka. Iqoqo lonke lamabhakhodi kufanele linqatshwe. Skena amabhakhodi usebenzisa isithwebuli sebhakhodi ukuze ufunde amabhakhodi, futhi uhlole ukuthi izinombolo namanani okufunda kuyahambisana yini. Ukwahlulelwa kwazo zonke iziphambeko kungokwereferensi kuphela. Uma ikhasimende linezidingo ezikhethekile, isahlulelo kufanele sisekelwe ezidingweni zekhasimende.

Isikhathi sokuthumela: May-11-2023