Ikhwalithi yokulala ethintana ngqo nesikhumba izothinta ngokuqondile induduzo yokulala. Isembozo sombhede yindawo yokulala evamile, esetshenziswa cishe kuyo yonke imizi. Ngakho lapho uhlola isembozo sombhede, yiziphi izici okudingeka ziqashelwe ngokukhethekile? Sizokutshela ukuthiniamaphuzu abalulekilekudingeka zihlolwe futhi yiziphi izindinganiso okufanele zilandelwe ngesikhathi sokuhlolwa!

Izindinganiso zokuhlola imikhiqizo kanye nokupakishwa

Umkhiqizo

1) akumele kube nezinkinga zokuphepha ngesikhathi sokusetshenziswa

2) ukubukeka kwenqubo akufanele konakaliswe, ukuklwejwa, ukuqhekeka, njll.

3) kufanele ihambisane nemithetho neziqondiso zezwe okuyiwa kulo kanye nezimfuneko zekhasimende

4) ukwakheka komkhiqizo nokubukeka, inqubo nezinto zokwakha kumele zihlangabezane nezidingo zamakhasimende kanye namasampula enqwaba

5) Imikhiqizo kufanele ihlangabezane nezimfuneko zekhasimende noma ibe nemisebenzi efanayo namasampuli eqoqo

6) Amalebula kufanele acace futhi ahambisane nezidingo zomthetho nezokulawula

I-1) Ukupakisha kufanele kufane futhi kuqine ngokwanele ukuze kuqinisekiswe ukwethembeka kwenqubo yokuthutha umkhiqizo

2) Izinto zokupakisha kumele zikwazi ukuvikela umkhiqizo ngesikhathi sokuhamba

3) Amamaki, amabhakhodi namalebula kufanele ahlangabezane nezidingo zamakhasimende noma amasampula eqoqo

I-4) Izinto Zokupakisha kufanele zihlangabezane nezidingo zamakhasimende noma amasampula eqoqo.

5) Umbhalo ochazayo, imiyalelo nezixwayiso zelebula ezihlobene kufanele ziphrintwe ngokucacile ngolimi lwezwe okuyiwa kulo.

6) Umbhalo ochazayo, izincazelo zemiyalo kufanele zihambisane nomkhiqizo kanye nemisebenzi ehlobene nayo.

1) Izindinganiso zokuhlola ezisebenzayo ISO 2859/BS 6001/ANSI/ASQ – Z 1.4 Uhlelo lwesampula olulodwa, ukuhlolwa okuvamile.

2) Izinga lesampula

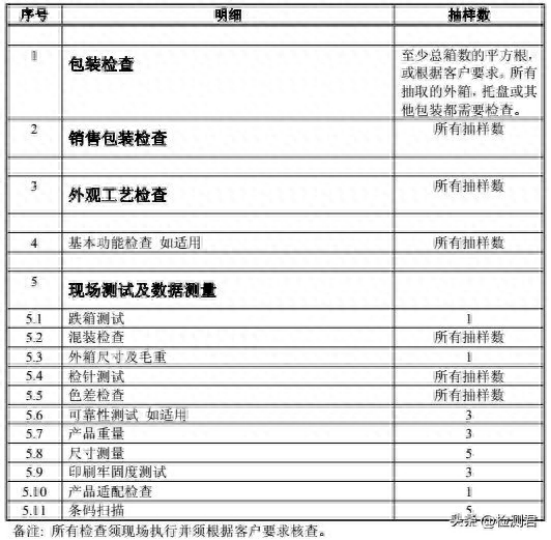

(1) Sicela ubhekisele enombolweni yamasampula kuleli thebula elilandelayo

(2) Umaamamodeli amaningi ahlolwa ndawonye, inombolo yesampula yemodeli ngayinye inqunywa iphesenti yenani laleyo modeli kuyo yonke inqwaba. Inombolo yesampula yalesi sigaba ibalwa ngokulinganayo ngokusekelwe kumaphesenti. Uma inombolo yesampula ebaliwe ingu-<1, khetha amasampuli angu-2 wesampula senqwaba, noma khetha isampula elilodwa lokuhlolwa okukhethekile kwezinga lesampula.

3) Izinga lekhwalithi eyamukelekayo i-AQL ayikuvumeli ukukhubazeka okungathi sína Ukukhubazeka okubucayiAQL xx Izinga lesici esibalulekile I-Major DefectAQL xx Izinga lokungaphumeleli okuncane Okuncane Okuncane Okuncane Qaphela: “xx” ikhombisa izinga lekhwalithi elamukelekayo elidingwa ikhasimende.

4) Inani lamasampula amasampula akhethekile noma amasampula angaguquki , Azikho izinto ezingafanelekile ezivunyelwe.

5) Izimiso ezijwayelekile zokuhlukanisa amaphutha

(1) Isici Esibucayi: Ukulimala okungathi sína, amaphutha abangela ukulimala komuntu siqu noma izici ezingaphephile lapho usebenzisa noma ugcina umkhiqizo, noma amaphutha aphula imithetho nezimiso ezifanele.

(2) Iphutha Elikhulu: Ukukhubazeka kokusebenza kuthinta ukusetshenziswa noma ubude besikhathi, noma amaphutha asobala athinta inani lokuthengisa lomkhiqizo.

(3) Isici Esincane: Isici esincane esingaphazamisi ukusetshenziswa komkhiqizo futhi asihlanganise lutho nevelu yokuthengisa yomkhiqizo.

6) Imithetho yokuhlolwa okungahleliwe:

(1) Ukuhlola kokugcina kudinga ukuthi okungenani i-100% yemikhiqizo ikhiqizwe futhi ithengiswe emaphaketheni, futhi okungenani ama-80% emikhiqizo apakishwe ebhokisini elingaphandle. Ngaphandle kwezidingo ezikhethekile zamakhasimende.

(2) Uma kutholakala amaphutha amaningi kusampula, isici esibi kakhulu kufanele siqoshwe njengesisekelo sokwahlulela. Wonke amaphutha kufanele ashintshwe noma alungiswe. Uma kutholakala amaphutha amakhulu, iqoqo lonke kufanele linqatshwe futhi ikhasimende lizonquma ukuthi lizikhulula yini izimpahla.

4. Inqubo yokuhlola nokuhlukaniswa kwamaphutha

Imininingwane yenombolo ye-serial Ukuhlelwa kokukhubazeka

1) Ukuhlolwa kokupakishwa Okubalulekile Okukhulu Okuncane Ukuvuleka kwesikhwama sePlastiki >19cm noma indawo >10x9cm, asikho isexwayiso sokuminza esiphrintiwe Uphawu lomsuka alukho Noma umswakama, njll. XX Impahla engalungile noma impahla yokupakisha engalungile X I-desiccant engalungile X Isiphanyeko esingalungile X Isiphanyeko esingekho X Ibhande elingekho noma enye ingxenye Izimpawu zokuxwayisa ngocansi azikho noma aziphrintiwe kahle

| 3) | Ukuhlolwa kwenqubo yokubukeka | X | ||

| Amakhoyili asengozini yokulimala | X | |||

| Unqenqema olucijile nendawo ecijile | X | |||

| Inaliti noma into yangaphandle yensimbi | X | |||

| Izingxenye ezincane emikhiqizweni yezingane | X | |||

| Iphunga | X | |||

| izinambuzane eziphilayo | X | |||

| amabala egazi | X | |||

| Ulimi olusemthethweni lwezwe okuyiwa kulo alukho | X | |||

| Izwe lendabuko elingekho | X | |||

| Intambo ephukile | X | |||

| intambo ephukile | X | |||

| ukuzulazula | X | X | ||

| Intambo enombala | X | X | ||

| intambo ephothiweyo | X | X | ||

| I-gauze enkulu yesisu | X | X | ||

| neps | X | X | ||

| Inaliti esindayo | X | |||

| umgodi | X | |||

| Indwangu eyonakele | X | |||

| amabala | X | X | ||

| amabala amafutha | X | X | ||

| amabala amanzi | X | X | ||

| Umehluko wombala | X | X | ||

| Izimpawu zepensela | X | X | ||

| Izimpawu zeglue | X | X | ||

| Uchungechunge | X | X | ||

| umzimba wangaphandle | X | X | ||

| Umehluko wombala | X | |||

| fade | X | |||

| I-Reflective | X | |||

| Uku-ayina okungalungile | X | X | ||

| zishile | X | |||

| Uku-ayina okungalungile | X | |||

| i-deformation yokucindezela | X | |||

| Ukucindezela nokwelula | X | |||

| Ama-Creases | X | X | ||

| imibimbi | X | X | ||

| goqa amamaki | X | X | ||

| imiphetho emangelengele | X | X | ||

| Inqanyuliwe | X | |||

| umgodi wokuwa womugqa | X | |||

| I-Jumper | X | X | ||

| Ukuncenga | X | X | ||

| Imithungo engalingani | X | X | ||

| Imithungo engajwayelekile | X | X | ||

| Inaliti yamagagasi | X | X | ||

| Ukuthunga akuqinile | X | |||

| Inaliti yokubuyisela embi | X | |||

| Amadethi angekho | X | |||

| I-jujube ebekwe kabi | X | |||

| Imithungo engekho | X | |||

| Ama-seam awayindawo | X | X | ||

| I-slack ye-tension yokuthunga | X | |||

| Imithungo exegayo | X | |||

| Izimpawu yenaliti | X | X | ||

| ama-sutures aphikisiwe | X | X | ||

| Qhuba | X | |||

| Ukushwabana | X | X | ||

| umthungo osontekile | X | |||

| umlomo/uhlangothi oluxegayo | ||||

| ukugoqa komthungo | X | |||

| Indlela yokugoqa umphetho ayilungile | X | |||

| Ama-seam awaqondanisiwe | X | |||

| ukushelela komthungo | X | |||

| Ukuthunga ngendlela engafanele | X | |||

| Ukuthunga indwangu engalungile | X | |||

| Awufaneleki | X | |||

| Akulungile | X | |||

| I-embroidery engekho | X | |||

| Ukungalungiswa kahle kwe-embroidery | X | |||

| Intambo ye-embroidery ephukile | X | |||

| Intambo yokufekethisa engalungile | X | X | ||

| Ukuphrinta ngokungalungile | X | X | ||

| uphawu lokuphrinta | X | X | ||

| ukuphrinta shift | X | X | ||

| fade | X | X | ||

| Iphutha lokunyathela | X | |||

| ukunwaya | X | X | ||

| Ukumboza kahle noma ukucwenga | X | X | ||

| Isisetshenziswa esingalungile | X | |||

| I-Velcro ilahlekile | X | |||

| I-Velcro engalingani | X | |||

| Umaka we-elevator awukho | X | |||

| Iphutha lemininingwane yelebula ye-elevator | X | |||

| Iphutha lelebula ye-elevator | X | |||

| Ulwazi lwelebula yekheshi engaphrintwe kahle | X | X | ||

| Ulwazi lwethegi ye-Elevator luvinjiwe | X | X | ||

| Ilebula ye-elevator ayivikelekile | X | X | ||

| Amalebula awaqondanisiwe kahle | X | |||

| Uphawu olugwegwile | X | X |

5 Ukuhlola okusebenzayo, ukukalwa kwedatha nokuhlola endaweni

1) Ukuhlola okusebenzayo: Oziphu, izinkinobho, izinkinobho ezifinyezwayo, ama-rivets, i-Velcro nezinye izakhi azisebenzi kahle. Umsebenzi uziphu awubushelelezi. XX

2) Ukulinganisa idatha kanye nokuhlolwa kwendawo

(1) Ukuhlolwa kokudonsa kwebhokisi ISTA 1A Ibhokisi lokudonsa, uma ukuphepha nokusebenza kutholakala kuntuleka noma kutholakala amaphutha abalulekile, lonke iqoqo lizonqatshwa.

(2) Ukuhlolwa kokupakishwa okuxubile kanye nezidingo zokupakisha okuxubile akuhlangabezani nezidingo zamakhasimende, lonke iqoqo lizonqatshwa.

(3) Ubukhulu nesisindo sebhokisi lomsila kufanele kuhambisane nokuphrinta kwebhokisi langaphandle, elivunyelwe. Umehluko +/-5%–

(4) Ukuhlolwa kokutholwa kwenaliti kwathola inaliti ephukile, futhi lonke iqoqo lanqatshwa ngenxa yensimbi yangaphandle.

(5) Ukuhlolwa komehluko wemibala kusekelwe ezidingweni zekhasimende. Uma kungekho sidingo, la mazinga okubhekisela alandelayo: a. Kunomehluko wombala esiqeshini esifanayo. b. .Umehluko wombala wento efanayo, umehluko wombala wemibala emnyama udlula 4~5, umehluko wombala wemibala ekhanyayo udlula 5. c. Umehluko wombala wenqwaba efanayo, umehluko wombala wemibala emnyama udlula 4, umehluko wombala wemibala ekhanyayo udlula 4~5, yonke inqwaba izonqatshwa.

(6)Oziphu, izinkinobho, inkinobho ye-snaps , i-Velcro nezinye izivivinyo zokuhlola ukuthembeka kokusebenza kokusetshenziswa okujwayelekile okungu-100. Uma izingxenye zonakalisiwe, ziphukile, zilahlekelwa umsebenzi wazo ojwayelekile, zenqabe yonke inqwaba noma zibangele ukukhubazeka ngesikhathi sokusetshenziswa.

(7) Ukuhlolwa kwesisindo kusekelwe ezidingweni zekhasimende. Uma kungekho sidingo, chaza ukubekezelela +/-3% futhi wenqabe yonke inqwaba.

(8) Ukuhlolwa kobukhulu kusekelwe ezidingweni zekhasimende. Uma kungekho sidingo, rekhoda ubukhulu bangempela obutholakele. Yenqaba yonke inqwaba

(9) Sebenzisa itheyiphu engu-3M 600 ukuhlola ukushesha kokuphrinta. Uma kukhona ukuphrinta okuxebukayo, a. Sebenzisa itheyiphu engu-3M ukuze unamathele kuphrinta bese ucindezela ngokuqinile. b. Susa i-tape ekushiseni kwama-degrees angu-45. c. Bheka itheyiphu nokuphrinta ukuze ubone ukuthi kukhona ukucwecwa kokuphrinta. Yenqaba yonke inqwaba

(10 ) Hlola ukuzivumelanisa nezimo Hlola ukuthi umkhiqizo ujwayelene nohlobo lombhede ohambisanayo Yenqaba yonke inqwaba

(11)Ukuskena ibhakhodiSebenzisa isithwebuli sebhakhodi ukuze ufunde ibhakhodi, noma izinombolo namanani okufunda ayahambisana. Yenqaba iqoqo lonke Amazwana: Ukwahlulela kwakho konke okungalungile kungesethenjwa kuphela, uma ikhasimende linezidingo ezikhethekile, kufanele lahlulelwe ngokuvumelana izidingo zekhasimende.

Isikhathi sokuthumela: Sep-21-2023