1, Ukuhlolwa kweTire kanyeukuhlolwa kwekhwalithi yokubukeka

Ikhwalithi yokubukeka kwethayi akufanele ibe nanoma yikuphi ukukhubazeka okuthinta impilo yesevisi yalo, njengokuhlukana phakathi kwezingxenye ezihlukahlukene, isipontshi, ukuphuka kweringi yezintambo, indandatho yocingo idonsela phezulu kanzima, ukuphuka kwentambo eminingi, ukushwabana kwentambo yangaphakathi, kanye unqenqema lomqhele ngentambo. Uma usebenzisa ibhande le-cushion, ukuma kwebhande le-cushion akufanele kube okungaphelele noma umzimba webhande akufanele uqhekeke.

2, Ukuhlolwa kwethaya, izimpawu zokuguga nokumaka

Ithayi ngalinye langaphandle kufanele lifakwe okungenani amamaki ama-4 abonakalayo okuguga cishe amabanga alinganayo eduze komjikelezo, futhi ukuphakama kwawo akumele kube ngaphansi kuka-1.6 mm.

Ithayi ngalinye kufanele libe nezimpawu emahlombe ezinhlangothini zombili ezibonisa indawo yophawu lokugqoka.

3, Ukulinganiswa kwedatha yokuhlola amathayi

1). Ukukalwa kwamapharamitha amasondo amakhulu

Ukucaciswa, inkomba yomthwalo (noma ileveli), umthamo womthwalo ohambisanayo nomfutho wokwehla kwamandla emali, amarimu akaliwe, usayizi omusha wesondo, ubukhulu bosayizi wokusetshenziswa, irediyasi yomthwalo omile, irediyasi eqengqelekayo, nokusetshenziswa okuvumelekile kwamasondo emoto kufanele kuhambisane ne-GB/T2978 noma imboni efanele. imibhalo yezobuchwepheshe.

2). Isondo lihlola usayizi omusha wonqenqema lwesondo

Ububanzi obuphelele nobubanzi obungaphandle bengxenye yamasondo buzohambisana nezinhlinzeko zeSithasiselo A,

3). Ukuxhumana phakathi kophawu lwejubane lesondo kanye nesivinini esiphezulu sokushayela

Ukuxhumana phakathi kwezimpawu zejubane lamathayi kanye nesivinini esiphezulu sokushayela kufanele kuhambisane nezinhlinzeko zeSithasiselo B

4). Ukuxhumana phakathi kwenkomba yomthwalo wesondo namandla omthwalo

Ukuxhumana phakathi kwenkomba yomthwalo wesondo namandla omthwalo kufanele kuhambisane nezinhlinzeko zeSithasiselo C.

4, Ukuhlolwa kweTireukuhlolwa kokusebenza kokuphepha

Ngokuvumelana nezidingo, yenza ukuhlolwa kokusebenza kwamandla, ukuhlolwa kokumelana nobuhlalu, ukuhlolwa kokusebenza kokuqina, ukuhlolwa kokusebenza kwengcindezi ephansi, nokuhlolwa kokusebenza kwesivinini esiphezulu emathangeni ayisampula.

1). Ukusebenza kwamandla esondo

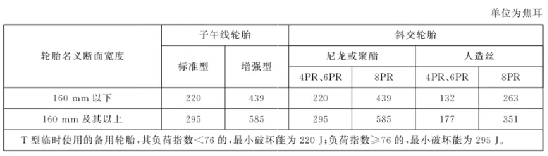

Ifanele amathayi ayi-diagonal, amathayi ayisipele esikhashana amise okwe-T, namathayi e-radial ane-aspect ratio yegama elingu-50 nangaphezulu. Ukuhlolwa kokusebenza kwamandla esondo kufanele kube namandla okuhluleka angekho ngaphansi kwenani elishiwo kuthebula elingezansi kuphoyinti lokuhlola ngalinye.

2). Ukumelana nobuhlalu besondo obungenayo i-tubeless

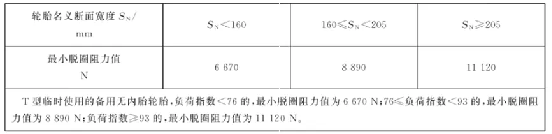

Ifanele amathayi angama-tubeless diagonal, amathayi ayisipele esikhashana amise okwe-T, namathayi angenawo amashubhu ane-radial ane-aspect ratio engu-50 nangaphezulu. Ukuhlolwa kokusebenza kokuqina kokuqina kobuhlalu besondo kufanele kube nobuhlalu obungaguqisi endaweni ngayinye yokuhlola engekho ngaphansi kwezinhlinzeko ezisethebulani elingezansi.

3). Ukusebenza kokuqina kwesondo

Ngemuva kokuhlolwa kokusebenza kokuqina, ukucindezela kwesondo akufanele kube ngaphansi kuka-95% wengcindezi yokuhlola yokuqala eshiwo; Ngemuva kokuthi ukuhlolwa sekuqediwe, akumele kube khona ukuhlukaniswa, ukuqhekeka kwe-ply, ukukhumula intambo, ukuphuka kwentambo, ukuphuka (ngaphandle kwamathayi eqhwa e-PTBC), ukuqhekeka kwamalunga, ukuqhekeka, noma ukonakala okungavamile komzimba wesondo ekuhlolweni kokubukeka. Uma isondo lonakele, ungqimba olungangeni moya kufanele luhlolwe.

4). Ukusebenza komfutho wesondo ophansi

Ifanele amathayi e-radial, kodwa ayifaki amathayi ayisipele esikhashana ohlobo lwe-T. Ngemuva kokuhlolwa kokusebenza komfutho ophansi wesondo, ingcindezi yesondo akufanele ibe ngaphansi kunomfutho wokuhlola oshiwo wokuqala, u-95%. Ngemuva kokuthi ukuhlolwa sekuqediwe, akufanele kube ne-delamination (ukunyathela, i-sidewall, i-ply, ungqimba olungangeni moya, ibhande noma ungqimba lwe-buffer, isondo), ukuqhekeka kwe-ply, ukucwecwa kwe-ply, ukuphuka kwe-ply, ukuphuka (ngaphandle kwamathayi eqhwa e-PTBC), ukuqhekeka ngokuhlanganyela, ukuqhekeka, nokuguqulwa okungavamile komzimba wesondo ekuhlolweni okubonakalayo.

5). Ukusebenza kwejubane eliphezulu kwamasondo

Ngemuva kokuhlolwa kokusebenza kwesivinini esiphezulu, ukucindezela kwesondo akufanele kube ngaphansi kuka-95% wengcindezi yokuhlola yokuqala eshiwo; Ngemuva kokuthi ukuhlolwa sekuqediwe, akumele kube khona i-delamination esobala (ukunyathela, udonga oluseceleni, ungqimba lwe-ply, ungqimba olungangeni moya, ungqimba lwebhande noma ungqimba lwe-buffer, ubuhlalu besondo), ukuqhekeka kongqimba, ukuhlubula kwe-ply, ukuqhekeka kwe-ply entsha, ukuqhekeka kwezimbali, ukuqhekeka okuhlangene, ukuqhekeka, noma ukuwohloka okungavamile kwesondo ngesikhathi sokuhlolwa okubonakalayo. Amathayi anesivinini esiphezulu esingu-300km/h noma ngaphezulu avunyelwe ukuba namabhamuza noma ukuqhuqha okubangelwa amabhamuza,

6). Ukuhlolwa kokusebenza kokumelana nokugingqika kwamasondo

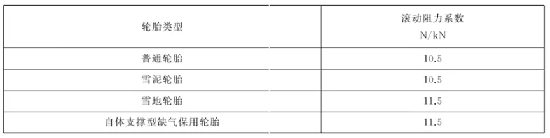

Isebenza emathayini e-radial, kodwa akubandakanyi amathayi anekhodi ye-rim diameter yegama engu-<10 kanye nekhodi ye-rim diameter yegama engu->25, kanye namasondo ayisipele okusetshenziswa okwesikhashana kuphela, amathayi anezinjongo ezikhethekile, amathayi omjaho, namathayi agxilile. I-coefficient yokumelana nokugoqeka yesondo akufanele yeqe inani eliphakeme lomkhawulo elishiwo kuthebula elingezansi.

7). Ukusebenza okulinganiselwe kokubambelela kwamasondo ezindaweni ezimanzi zomgwaqo

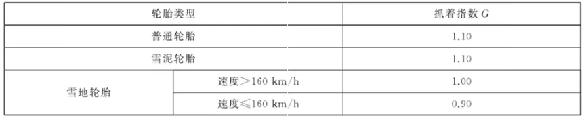

Isebenza emathayini e-radial, kodwa akubandakanyi amathayi anekhodi ye-rim diameter yegama engu-<10 kanye nekhodi ye-rim diameter yegama engu->25, kanye namasondo ayisipele okusetshenziswa okwesikhashana kuphela, amathayi anezinjongo ezikhethekile, amathayi omjaho, namathayi agxilile. Inkomba yokubamba ehlobene yomgwaqo omanzi wesondo akufanele ibe ngaphansi kwenani elilinganiselwe elilinganiselwe elishiwo kuThebula lesi-4.

Okungenhla kungamazinga nezindlela zokuhlolwa kwamasondo emoto, okuhlanganisa ukuhlolwa kwekhwalithi yokubukeka kwamasondo, ukukalwa kwepharamitha eyinhloko, ukuhlolwa kokusebenza kokuphepha, njll.

Isikhathi sokuthumela: Jul-10-2024