Ngokusho kwe-CNN, isibalo sezisulu zokusha kwefulethi laseBronx eMeya yeDolobha laseNew York u-Eric Adams ngoJanuwari 9, ngesikhathi sendawo, sasingu-17, kuhlanganisa nabantu abadala abangu-9. kanye nezingane ezingu-8 zibike ukuthi ngokusekelwe ebufakazini obusendaweni yesigameko kanye nobufakazi bofakazi bokuzibonela, kwaqale kwatholakala ukuthi umlilo udalwe isakhamuzi esisebenzisa i-heater "engasebenzi kahle" ekamelweni.

Izinga eliphoqelekile lezwe lethu lezidingo ezikhethekile zokuphepha zama-heater angaphakathi endlini kanye nezinhloso ezifanayo lilingana ne-IEC 60335-2-30: 2004, eyenza izidingo ezihambisanayo zama-heater kagesi.

Ukuhlolwa kwe-heater kagesi

1. Ukuvikelwa ekuxhumaneni nezingxenye ezibukhoma

2. Amandla okufaka kanye namanje

3. Umkhuhlane

4. Ukuvuza kwamandla amanje namandla kagesi ekushiseni okusebenzayo

5. I-overvoltage edlulayo

6. Ukumelana nomswakama

7. Ukuvuza kwamandla amanje namandla kagesi

8. Ukuvikelwa kokulayisha ngokweqile kwama-transformer namasekethe ahlobene

9. Ukuzinza kanye nezingozi zemishini

10. Amandla omshini

11. Izintambo zangaphakathi

12. Izinyathelo zokubeka phansi

13. Ukusula, amabanga ama-creepage kanye nokufakwa okuqinile

14. Ukumelana nokushisa nelangabi

1.Ukuvikela ekuxhumaneni nezingxenye ezibukhoma

Ukwakhiwa kanye nokuvaleka kwento esetshenziswayo kuzohlinzeka ngokuvikeleka okwanele ekuthinteni ngengozi izingxenye ezibukhoma.

2.Amandla okufaka kanye namanje

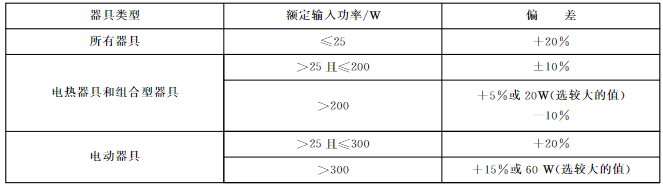

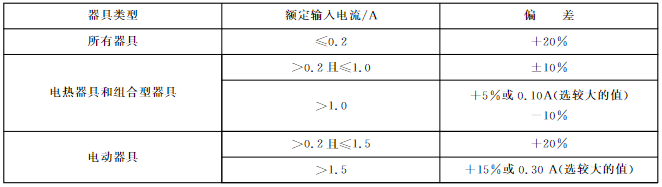

Uma into esetshenziswayo imakwe ngokokufaka kwamandla alinganiselwe, okokufaka kwamandla okusebenza akufanele kuphambuke kokokufaka kwamandla okulinganiselwe okungaphezu kokuchezuka okuboniswe kuthebula elingezansi kuzinga lokushisa elivamile lokusebenza.

Uma into esetshenziswayo imakwe ngeledlule elilinganiselwe, lamanje ekushiseni okujwayelekile kokusebenza ngeke lisuke kumanje elilinganiselwe ngaphezu kwenani elihambisanayo lokuchezuka elinikezwe kuthebula elingezansi.

3. Umkhuhlane

Ngesikhathi sokusetshenziswa okuvamile, into esetshenziswayo nendawo ezungezile akufanele ifinyelele emazingeni okushisa adlulele.

4. Ukuvuza kwamandla amanje namandla kagesi ekushiseni okusebenzayo

4.1 Emazingeni okushisa okusebenza, ukuvuza kwamandla kagesi akufanele kudlulele, futhi amandla ayo kagesi kufanele ahlangabezane nezidingo ezicacisiwe. Imishini yokushisisa ngogesi isebenza izikhathi ezingu-1.15 amandla okufaka alinganiselwe. Izinto zikagesi kanye nenhlanganisela yezinto zikagesi zinikwa amandla izikhathi ezingu-1.06 ze-voltage elinganisiwe. Imiyalo yokufaka icacisa ukuthi izinto zikagesi zezigaba ezintathu ezivela ekuphakeleni kwesigaba esisodwa nazo zingasetshenziswa futhi amasekhethi amathathu axhunywe ngokuhambisana angase ahlolwe njengezinto zikagesi zesigaba esisodwa. Nqamula i-impedance evikelayo nesihlungi sokuphazamiseka komsakazo ngaphambi kokwenza lolu hlolo.

Ngemuva kokuthi into esebenza isikhathi eside iqhubeka nokusebenza isikhathi eside esihambisana nezimo ezimbi kakhulu ekusetshenzisweni okujwayelekile, amandla okuvuza akumele adlule amanani alandelayo:

- 0.25 mA ezintweni zikagesi zeClass II

-0.5mA Yekilasi 0, i-OI nezinto zikagesi zezitsha

- 0.75 mA yezinto zikagesi eziphathwayo zeClass I

- 3.5mA yezinto zikagesi ezimile zeClass I

- Ezintweni ezishisisa ugesi ezinganyakazi ze-Class I, 0.75mA noma 0.75 mA/kW (amandla okufaka alinganiselwe ento esetshenziswayo), kuye ngokuthi iyiphi enkulu, kodwa umkhawulo ngu-5mA

Ezimpahleni zikagesi ezihlanganisiwe, inani eliphelele lokuvuza lamanje lingase libe phakathi kwemikhawulo eshiwo ezinsizeni zikagesi zokushisisa noma izinto zikagesi, kuye ngokuthi iyiphi enkulu, kodwa imikhawulo emibili ayinakwengezwa.

5.I-overvoltage edlulayo

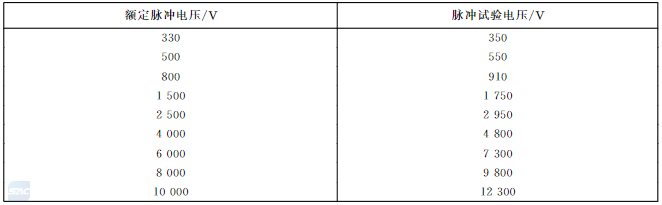

Into esetshenziswayo izokwazi ukumelana no-overvoltage wesikhashana okungenzeka ukuthi ifakwe kukho. Nquma ukuthi ifaneleka yini ngokwenza ukuhlolwa kwe-pulse voltage kugebe ngalinye elincane kunevelu eshiwo kuthebula elingezansi.

6. Ukumelana nomswakama

Izindlu zikagesi zizohlinzeka ngezinga elifanelekile lokuvimbela amanzi.

7. Ukuvuza kwamandla amanje namandla kagesi

Ukuvuza kwamandla kagesi akufanele kudlulele, futhi amandla ayo kagesi kufanele ahlangabezane nezidingo ezicacisiwe.

I-voltage yokuhlola ye-AC isetshenziswa phakathi kwezingxenye ezibukhoma nezingxenye zensimbi ezifinyelelekayo ezixhunywe kucwecwe lwensimbi. Indawo ye-foil yensimbi exhunyiwe ayidluli ku-20cmx10cm, futhi ixhumene nendawo efinyelelekayo yezinto zokuvikela.

I-voltage yokuhlola:

- Ezinsizeni zesigaba esisodwa, izikhathi ezingu-1.06 ze-voltage elinganisiwe;

- Ezintweni zikagesi ezinezigaba ezintathu, izikhathi ezingu-1.06 i-voltage elinganiselwe ihlukaniswa ngo-/3.

Phakathi nemizuzwana emi-5 ngemva kokufaka i-voltage yokuhlola, linganisa ukuvuza kwamanje.

Ukuvuza kwamanje akufanele kudlule amanani alandelayo:

- Ngezinto zikagesi zeClass II: 0.25 mA

- Okwezinto zikagesi zeClass 0, Class 0I kanye neSichuan Class: 0.5mA

- Okwezinto zikagesi eziphathwayo zeClass I: 0.75mA

- Okwezinto zikagesi ezimile zeClass I: 3.5mA

- Ezinsizeni zikagesi ezimile zekilasi I: 0.75mA noma 0.75mA/kW (amandla okufaka alinganiselwe ento esetshenziswayo), kuye ngokuthi yikuphi okukhulu,

Kodwa ubukhulu be-5mA.

Uma zonke izilawuli zinendawo evulekile kuzo zonke izigxobo, inani elishiwo ngenhla lomkhawulo wamanje wokuvuza liphindwe kabili. Umkhawulo wamanje wokuvuza oshiwo ngenhla uzophinda uphindwe kabili uma:

- Kunenye kuphela i-thermal circuit breaker kumshini futhi azikho ezinye izilawuli, noma

- Wonke ama-thermostat, imikhawulo yezinga lokushisa kanye nezilawuli zamandla azinayo indawo yokuvala, noma

-Umshini ufakwe isihlungi sokuphazamisa umsakazo. Kulesi simo, ukuvuza kwamanje lapho kunqanyulwa isihlungi akufanele kudlule umkhawulo oshiwo.

Ezimpahleni zikagesi ezihlanganisiwe, inani eliphelele lokuvuza lamanje lingase libe ngaphakathi kwemikhawulo yezinto zikagesi zokushisisa noma izinto zikagesi, kungakhathaliseki ukuthi yimuphi umkhawulo omkhulu, kodwa imikhawulo emibili ayikwazi ukungezwa ndawonye.

Ngokushesha ngemva kokuhlolwa okungenhla, ukwahlukanisa kungaphansi kwamandla kagesi wegagasi le-sinusoidal eliyisisekelo elinemvamisa engu-50 Hz noma engu-60 Hz iminithi elingu-1. Ithebula elilandelayo linikeza

Amanani we-voltage wokuhlola asebenza ezinhlotsheni ezahlukene zokufakelwa anikezwa. Izingxenye ezifinyelelekayo ze-insulation material kufanele zimbozwe nge-foil yensimbi.

8. Ukuvikelwa kokulayisha ngokweqile kwama-transformer namasekethe ahlobene

Imishini enesekhethi enikwe amandla yi-transformer izokwakhiwa ngendlela yokuthi amazinga okushisa adlulele angenzeki ku-transformer noma kumasekethe ahlotshaniswa ne-transformer lapho isifunda esifushane singase senzeke ngesikhathi sokusetshenziswa okuvamile.

Ukuthobelana kunqunywa ngokusebenzisa izimo ze-short-circuit ezimbi kakhulu noma ukugcwala ngokweqile okungenzeka kwenzeke ekusetshenzisweni okuvamile. I-voltage yokuhlinzeka yomshini izikhathi ezingu-1.06 noma izikhathi ezingu-0.94 i-voltage elinganisiwe, noma yikuphi okungekuhle kakhulu. Inani lokunyuka kwezinga lokushisa longqimba olufakwayo lwezintambo ekuvikelekeni kwamasekhethi kagesi aphansi kakhulu akufanele lidlule ku-15K yenani elishiwo elifanele kuThebula 3.

9. Ukuzinza kanye nezingozi zemishini

Izishisi eziphathwayo kufanele zizinze ngokwanele. Izifudumezi ezifakwe amasokhethi kagesi kufanele zifakwe ukuhlanganiswa kwentambo. Beka i-heater nge-engeli engu-15 ° ukuya evundlile endaweni engathandeki kakhulu ukuze isetshenziswe ngokujwayelekile. I-heater akufanele idlule.

I-heater enesisindo esingaphezu kwe-5 kg ibekwe endaweni evundlile futhi amandla angu-5N + - 0.1N asetshenziswa phezulu kwe-heater ngendlela engathandeki kakhulu evundlile. I-heater kagesi akufanele idlule.

10. Amandla omshini

Imishini kufanele ibe namandla anele emishini futhi izokwakhiwa ukuze imelane nokuphathwa kabi nokubamba okungenzeka kwenzeke ekusetshenzisweni okuvamile. Sebenzisa i-spring impactor ukwenza ukuhlolwa komthelela kumshini. Into esetshenziswayo isekelwa ngokuqinile futhi amandla omthelela angu-0.5J athintwa izikhathi ezintathu kuwo wonke amaphuzu angaba buthaka wegobolondo likagesi.

Kumahitha ama-elementi awo okushisa axhumene ngqo nephaneli yengilazi, i-spring impactor kufanele isetshenziselwe ukuthinta iphaneli, futhi amandla omthelela ngu-2 J.

Izifudumezi ezikhazimulayo ezibonakalayo, ngaphandle kwalezo ezifakwe ezindaweni eziphezulu, kufanele zibekwe ukuze ingxenye emaphakathi yekhava yokuvikela umlilo ibe sendaweni evundlile. Beka isisindo esiphansi esiphansi esinesisindo esingu-5 kg kanye nobubanzi obuyi-100 mm phakathi nendawo yekhava yokuvikela umlilo imizuzu engu-1. Ngemva kokuhlolwa, ikhava yokuvikela umlilo ngeke ibonise ukuguga okuphawulekayo okuhlala njalo.

11. Izintambo zangaphakathi

Izindlela zokuhamba kufanele zibe bushelelezi futhi zingabi nemiphetho ebukhali. Izintambo kufanele zivikelwe ukuze zingahlangani nama-burrs, amaphiko okupholisa noma imiphetho efanayo engase ibangele ukulimala kokuvala. Izimbobo zensimbi okudlula kuzo izintambo ezivalekile kufanele zibe nendawo eyisicaba, eyindilinga noma umkhono ovikelayo. I-wiring kufanele ivinjwe ngokuphumelelayo ukuthi ingathintani nezingxenye ezihambayo, futhi ukufaneleka kwayo kufanele kunqunywe ngokuhlola okubonakalayo.

- Ubuhlalu obuvikelayo kanye nezivikeli ze-ceramic ezifanayo kumakhondakta aphilayo kufanele zilungiswe noma zisekelwe ukuze zingakwazi ukushintsha indawo noma ziphumule emakhoneni acijile. Uma ubuhlalu be-insulating busemseleni wensimbi oguquguqukayo, buzovalwa kumkhono we-insulating ngaphandle uma ipayipi ingakwazi ukuhamba ngesikhathi sokusetshenziswa okuvamile. Ukuthobelana kunqunywa ukuhlola nokuhlola mathupha.

- Izingxenye ezihlukene zomshini okwazi ukuhamba ngokuhlobene ngesikhathi sokusetshenziswa okuvamile noma ukunakekelwa komsebenzisi ngeke zibangele ingcindezi engadingekile ekuxhumekeni kukagesi namakhondatha angaphakathi, okuhlanganisa amakhondatha ahlinzeka ngokuqhubeka komhlaba. Amapayipi ensimbi aguquguqukayo ngeke abangele ukulimala kokufakwa kwamakhondatha aqukethwe ngaphakathi kwawo. Imithombo yamakhoyili evulekile ngeke isetshenziselwe ukuvikela amakhondatha. Uma isiphethu sekhoyili esinamakhoyili athintanayo sisetshenziselwa ukuvikela umqhubi, ulwelwesi olufanele lokuvikela kumele lwengezwe ku-insulation of the conductor.

- Uma ukugoba kwenzeka ngesikhathi sokusetshenziswa okujwayelekile, beka umshini endaweni yawo evamile ukuze usetshenziswe futhi uwunikeze amandla kagesi alinganiselwe ngaphansi kwezimo ezivamile zokusebenza. Izingxenye ezinyakazayo ziya phambili nangemuva ukuze zigobe ucingo ngaphakathi kwe-engeli ephezulu evunyelwe isakhiwo. Izinga lokugoba izikhathi ezingama-30/min. Inombolo yokugoba ithi:

Okwezintambo ezizogoba ngesikhathi sokusebenza okujwayelekile, izikhathi eziyi-10,000;

Izikhathi eziyi-100 zezintambo ezigobile ngesikhathi sokulungiswa komsebenzisi.

- Izintambo zangaphakathi eziveziwe zizoqina futhi zizovikelwa ukuze uma zisetshenziswa okuvamile amabanga angakwazi ukuncishiswa ngaphansi kwamanani ashiwo.

-I-insulation ye-wiring yangaphakathi kufanele ikwazi ukumelana nezingcindezi zikagesi ezingase zenzeke ngesikhathi sokusetshenziswa okuvamile. Ukusebenza kukagesi kwe-insulation eyisisekelo kufanele kulingane nokufakwa okuyisisekelo kwezintambo eziguquguqukayo ezicaciswe ku-GB 5023.1 noma ku-GB 5013.1, noma kuthobelane nokuhlolwa kwamandla kagesi okulandelayo.

- Faka i-voltage engu-2000V phakathi kocingo nocwecwe lwensimbi olugoqwe ngaphandle kwesendlalelo sokushisa imizuzu engu-15. Akufanele kube nokuhlukana.

-Lapho i-bushing isetshenziswa njenge-insulation eyengeziwe ye-wiring yangaphakathi, izobanjwa ngendlela ethembekile.

Ukuthobelana kuhlolwa ngokuhlolwa nangokuhlolwa okwenziwa ngesandla.

- Ikhondaktha enemibala emibili enemibala ephuzi/eluhlaza kufanele isetshenziswe kuphela njengesikhondatha esiphansi. Ukuthobelana kunqunywa ngokuhlola.

12. Izinyathelo zokubeka phansi

- Izingxenye zensimbi ezifinyelelekayo ze-Class OI kanye nezinto zikagesi ze-Class I ezingase zibe bukhoma uma kwenzeka kuba nokungasebenzi kahle kwe-insulation zizoxhunywa unomphela futhi ngendlela enokwethenjelwa kutheminali yomhlaba ngaphakathi kwento esetshenziswayo, noma endaweni ethinta umhlaba kusokhethi okokufaka kagesi.

-Itheminali yaphansi kanye nokuthintana komhlabathi akufanele kuxhunywe endaweni engathathi hlangothi.

Izinto zikagesi ze-Class 0, Class II kanye ne-Sichuan ngeke zibe nezinyathelo zokubeka phansi. Amasekhethi kagesi aphansi kakhulu okuphepha akufanele axhunywe emhlabeni ngaphandle uma engamasekhethi kagesi avikelayo aphansi kakhulu. Ukuthobelana kunqunywa ngokuhlola.

-Idivaysi yokunamathisela yetheminali yaphansi kufanele ivikeleke ngokwanele ukuvikela ukuxega ngephutha.

Kwezinye izakhiwo, izinyathelo ezikhethekile zingadingeka, njengokusetshenziswa kwengxenye engakwazi ukuqedwa ngokunganaki ngengozi.

Amatheminali asetshenziselwa ukuxhuma amakhondaktha angaphandle we-equipotential azovumela ukuxhunywa kwamakhondatha anendawo ebizwa ngokuthi i-cross-sectional kusuka ku-2.5 mm2 kuya ku-6 mm2, futhi ngeke asetshenziselwe ukunikeza ukuqhubeka komhlaba phakathi kwezingxenye ezihlukene zomshini. Akufanele kwenzeke ukuxegisa lezi zintambo ngaphandle kosizo lwamathuluzi. Ukuthobelana kunqunywa ukuhlola nokuhlola mathupha.

- Uma ingxenye ekhiphekayo enoxhumo lomhlaba ifakwe kwenye ingxenye yomshini, ukuxhumana kwayo komhlaba kuyokwenziwa ngaphambi koxhumano oluphethe manje futhi lapho ingxenye ihoxiswa, uxhumano lomhlaba luzophulwa ngemva kokuba uxhumano oluphethe manje seluphelile. inqanyuliwe.

Ezimpahleni zikagesi ezinentambo kagesi, ubude bekhondakta phakathi kwetheminali noma intambo kanye netheminali buzoba ngendlela yokuthi uma intambo ishelela ngaphandle kwentambo, ikhondukta ephethe manje izonyakaziswa phambi kwekhondatha yaphansi. Ukuthobelana kunqunywa ukuhlola nokuhlola mathupha.

- Zonke izingxenye zamatheminali omhlaba ezihloselwe ukuxhunywa kumakhondaktha angaphandle ngeke zingabi nabungozi bokugqwala obuvela ngokuthinta ithusi le-conductor yomhlaba, noma ekuxhumaneni nezinye izinsimbi.

Izingxenye ezisetshenziselwa ukunikeza ukuqhubeka komhlaba ziyoba ezensimbi ekwazi ukumelana nokugqwala okwanele, ngaphandle kohlaka lwensimbi noma izingxenye ezivalekile. Uma lezi zingxenye zenziwe ngensimbi, ukujiya kwe-plating okungenani okungu-5 μm kuzonikezwa ebusweni bomzimba. Izingxenye zensimbi ezinamekwe noma ezingagcotshiwe ezihloselwe kuphela ukuhlinzeka noma ukudlulisa ingcindezi yokuxhumana kufanele zivikelwe ngokwanele ekugqwaleni.

Uma umzimba wetheminali yomhlaba uyingxenye yohlaka noma indawo evalekile eyenziwe nge-aluminium noma ama-alloys e-aluminium, kufanele kuthathwe izinyathelo zokugwema ubungozi bokugqwala obuvela ngokuthinta ithusi ne-aluminium noma ama-alloys e-aluminium. Ukuthobelana kunqunywa ngokuhlola nokulinganisa.

- Ukuxhumana phakathi kwetheminali yaphansi noma ukuthintana komhlabathi kanye nengxenye yensimbi esekelwe phansi kuzoba nenani eliphansi lokumelana.

Le mfuneko ayisebenzi kumadivayisi axhumayo ahlinzeka ngokuqhubeka komhlaba kumasekhethi kagesi aphansi kakhulu avikelwe uma ukucaciswa kokufakwa kwesisekelo kumasekhethi kagesi aphansi kakhulu avikelwe kucaciswa ngokusekelwe ku-voltage elinganiselwe yento esebenza ngayo.

-Imikhondo ephrintiwe kumabhodi wesekethe ephrintiwe ezintweni eziphathwa ngesandla ngeke isetshenziselwe ukunikeza ukuqhubeka komhlaba. Ukuqhubeka komhlaba kungase kuhlinzekwe kwezinye izinto uma lezi zimo ezilandelayo zihlangatshezwana nazo:

- Okungenani kunemigqa emibili enamajoyinti azimele e-solder, futhi izidingo ze-27.5 kufanele zihlangabezane nomshini ngamunye wesekethe;

-Impahla yebhodi lesifunda ephrintiwe ihambisana nezidingo ze-IEC 60249-2-4 noma i-IEC 60249-2-5.

Ukuthobelana kunqunywa ukuhlolwa nokuhlolwa okufanele.

13. Ukusula, amabanga ama-creepage kanye nokufakwa okuqinile

Izinto ezisetshenziswayo kufanele zakhiwe ngendlela yokuthi izindawo ezisuswayo, amabanga e-creepage kanye nokuvala okuqinile kwanele ukumelana nezingcindezi zikagesi into engase ibhekane nazo.

Uma ama-coatings asetshenziswa kumabhodi esekethe aphrintiwe ukuze kuvikelwe i-microenvironment (i-Class A coatings) noma ukunikeza ukufakwa okuyisisekelo (i-Class B), i-Appendix J iyasebenza. Ukungcoliswa kweleveli 1 kufakwa ezindaweni ezincane kusetshenziswa okokunamathela ku-Class A. Uma usebenzisa i-Coating ye-Class B, azikho izidingo zokucaciswa kukagesi namabanga ama-creepage.

- Uma kucatshangelwa ama-voltage alinganisiwe we-impulse izigaba ze-overvoltage kuThebula 15, ukucaciswa ngeke kube ngaphansi kwamanani ashiwo kuThebula 16, ngaphandle kwalapho imvume phakathi kokufakwa okuyisisekelo nokufakwa kwe-functional insulation ihlangabezana nokuhlolwa kwamandla kagesi eSahluko 14. Kodwa-ke, uma ibanga esakhiweni lithintwa ukuguga, ukuwohloka, ukunyakaza kwengxenye noma ukuhlangana, imvume kagesi ehambisanayo kufanele inyuswe ngo-0.5mm lapho kulinganiswa. I-pulse voltage ingu-1500V noma ngaphezulu, futhi ukuhlolwa kwe-pulse voltage akusebenzi.

14. Ukumelana nokushisa nelangabi

Ezingxenyeni zangaphandle ezenziwe ngezinto ezingezona ezensimbi, izingxenye ze-insulating ezisetshenziselwa ukusekela izingxenye ezibukhoma (kuhlanganise nezixhumi), kanye nezingxenye zempahla eshwabana ukushisa ehlinzeka ngokufakwa kwensizakalo noma ukwahlukanisa okuqinisiwe,

I-United States, i-Canada, i-European Union kanye ne-Australia zonke zinezindinganiso zazo zokuphepha zemikhiqizo enjalo. Ikakhulukazi iziteshi ze-Amazon 3 zinezidingo ezikhethekile.

Izinga laseMelika: UL 1278

I-Canadian Standard: CSA C22.2 No.46

Izinga le-EU: EN 60335-2-30

Izinga laseBrithani: BS EN 60335-2-30

Izinga lamazwe ngamazwe: IEC 60335-2-3

Izinga lase-Australia: AS/NZS 60335.2.30

Isikhathi sokuthumela: Dec-29-2023