1. Ububanzi

Izidingo zobuchwepheshe nezinto zokuhlola izimo zokusetshenziswa, ukusebenza kukagesi, izakhiwo zemishini kanye nokusebenza kwemvelo kwamabhethri ayisisekelo e-lithium (amabhethri ewashi, ukufundwa kwamamitha okucisha ugesi), njll., kuhlanganisa izindinganiso zokwamukela ukwamukelwa kwamabhethri e-lithium primary.

Ukwamukelwa, ukuqinisekiswa okuvamile, nokuhlolwa kokusebenza okugcwele kwamabhethri e-lithium primary

Izinga lokushisa eliphakeme neliphansi elishintshanisa umswakama negumbi lokuhlola ukushisa

Igumbi lokuhlola isifutho sikasawoti

I-Vernier caliper

Isihloli sokusebenza kwebhethri

Idivayisi yokuhlola ukudlidliza

Idivayisi yokuhlola umthelela

i-multimeter

3.1 Izidingo zokupakisha

Idizayini yokupakisha kufanele ihambisane nemvelo, izici kanye nezimo zokugcinwa nezokuthutha zomkhiqizo. Ibhokisi lokupakisha kufanele limakwe ngegama lomkhiqizi, igama lomkhiqizo, imodeli yomkhiqizo, usuku lokukhiqizwa kanye nenani lokupakisha. Ingaphandle lebhokisi lokupakisha kufanele liphrintwe noma linamathiselwe izimpawu zokuthutha njengokuthi "Phatha Ngokunakekela", "Ukwesaba Ukumanzi", "Phezulu" njalonjalo. Ama-logo aphrintiwe noma anamathiselwe ngaphandle kwebhokisi lokupakisha akumele afiphele noma awe ngenxa yezimo zokuhamba nezimo zemvelo. Ibhokisi lokupakisha kufanele lihlangabezane nezidingo zokuvikela umswakama, ukumelana nothuli kanye nokungethuki. Ingaphakathi lephakeji kufanele libe nohlu lokupakisha, isitifiketi somkhiqizo, izesekeli namanye amadokhumenti angahleliwe afanelekile.

3.2 Izidingo eziyisisekelo

3.2.1 Ibanga lokushisa

Izinga lokushisa le-ambient kufanele lihambisane nethebula elingezansi.

| Cha. | Uhlobo Lwebhethri | izinga lokushisa (℃) |

| 1 | ibhethri lewashi (Li-SOCl2) | - 55 - 85 |

| 2 | Ibhethri yokufunda imitha yokucisha ugesi(Li-MnO2) | - 20 - 60 |

3.2.2 Ibanga lokuswakama

Umswakama ohlobene womoya kufanele uhambisane nethebula elingezansi.

| Cha. | Isimo | Umswakama ohlobene |

| 1 | Isilinganiso ngonyaka | <75% |

| 2 | Izinsuku ezingama-30 (lezi zinsuku zisakazwa ngokwemvelo unyaka wonke) | 95% |

| 3 | Kuvele ngenhlanhla kwezinye izinsuku | 85% |

3.2.3 Umfutho womkhathi

63.0kPa~106.0kPa (ukuphakama okungu-4000m nangaphansi), ngaphandle kwezidingo ze-oda elikhethekile. Izindawo eziphakeme kakhulu zidinga ukusebenza okujwayelekile endaweni ephakeme ka-4000m kuya ku-4700m.

Amabhethri ayinhloko e-lithium kufanele okungenani amakwe ngegama lomkhiqizi, igama lokuhweba noma uphawu lokuhweba, idethi yokukhiqiza, imodeli, amandla kagesi, amandla okuzisholo, kanye nophawu lwesitifiketi sokuphepha. Amabhethri kufanele amakwe ngokuthi "Isexwayiso" futhi abe nalokhu okulandelayo noma okulingana nalokho: "Ibhethri isengozini yomlilo, ukuqhuma nokusha. Ungashajeli, uhlakaze, uminyanise, ushise ngaphezu kuka-100°C noma ushise. Ligcine kuphakheji yokuqala. ngaphambi kokusetshenziswa. "Okuqukethwe okumakiwe kufanele kuhambisane nemininingwane yobuchwepheshe.

Ukucaciswa okuningiliziwe kobuchwepheshe bebhethri ye-lithium eyinhloko ihlanganisa okungenani i-voltage yegama, i-voltage yesekethe evulekile, izinga lokushisa lokusebenza, amandla okuzisholo, amandla okuzisholo, ukusebenza kwe-pulse, ubuningi obuqhubekayo bokuphuma kwamanje, isilinganiso sonyaka sokuzikhipha ngokwakho, usayizi, ifomu lesixhumi, uphawu lokuhweba, kanye ukukhiqiza Ilogo yenkampani yokuhlonza nokunye okuqukethwe.

(1) Vula i-voltage yesifunda

(2) I-voltage yokulayisha

(3) Ukusebenza kwe-Pulse

(4) Ukusebenza kwe-passivation

(5) Amandla okuqamba (asebenza ekuhlolweni kokusebenza okugcwele)

3.5Izidingo zokusebenza kwemishini

Ibhethri kufanele ihlolwe amandla etheminali, ukuhlolwa komthelela, kanye nokuhlolwa kokudlidliza okucaciswe kokungu-5.6 kwaleli zinga lokuhlola. Ngemuva kokuhlolwa, ibhethri ngeke ivuze, ikhiphe, i-short-circuit, iqhume, iqhume, noma ibambe umlilo, futhi ucezu lwe-welding ngeke lube nokuphuka noma umonakalo obonakalayo. Ikhwalithi Izinga lokushintsha lingaphansi kuka-0.1%.

3.6 Ukusebenza kwe-soldering

3.6.1 Ukuthengiselana (kusebenza ezinhlotsheni ezinamathebhu ensimbi)

Uma ibhethri ihlolwa ngo-5.7.1 waleli zinga lokuhlola, amandla okumanzisa akufanele abe ngaphansi kwamaphesenti angama-90 wamandla okumanzisa okucatshangelwayo.

3.6.2 Ukumelana nokushisa okushiselayo (kusebenza ezinhlotsheni ezinamathebhu okushisela ensimbi)

Ibhethri ingaphansi kokuhlolwa okungu-5.7.2 kwaleli zinga lokuhlola. Ngemuva kokuhlolwa, ukubonakala kwebhethri eyinhloko ye-lithium ayinawo umonakalo womshini. Ukuhlolwa kukagesi kufanele kuhambisane nezidingo ezifanele zokucaciswa kobuchwepheshe.

3.7 Izidingo zokusebenza kwemvelo (zisebenza ekuhlolweni kokusebenza okugcwele)

Amabhethri ayinhloko e-lithium ahlolwa indawo ezungezile engu-5.8 yaleli zinga lokuhlola. Ukuhlolwa kukagesi okwenziwa ngemva kokuhlolwa kuzohambisana nezidingo zobuchwepheshe ezifanele zemininingwane yayo yobuchwepheshe.

3.8 Ukuhlolwa kokuphepha (kusebenza ekuhlolweni kokusebenza okugcwele)

Amabhethri e-lithium primary kufanele ahlangabezane nezidingo zobuchwepheshe ezilandelayo lapho enza izivivinyo zokuphepha ngo-5.9 waleli zinga lokuhlola.

| Cha. | Amaphrojekthi wokulinga | Imfuneko |

| 1 | ukuphakama okuphezulu sekulingisa | Akukho ukuvuza, akukho okuphumayo, akukho ukujikeleza okufushane, akukho ukugqashuka, akukho kuqhuma, akukho mlilo,Izinga lokushintsha kwenqwaba kufanele libe ngaphansi kuka-0.1%. |

| 2 | ukuwa kwamahhala | |

| 3 | isifunda esifushane sangaphandle | Ayishisi, ayiqhume, ayiqhume noma ibambe umlilo. |

| 4 | Umthelela wento esindayo | Akukho kuqhuma, akukho mlilo. |

| 5 | i-extrusion | |

| 6 | Ukushaja okungavamile | |

| 7 | Ukukhipha okuphoqiwe | |

| 8 | ukuhlukunyezwa okushisayo |

4. Izindlela zokuhlola

4.1 Izidingo ezijwayelekile

4.1.1Izimo zokuhlola

Ngaphandle kwalapho kucaciswe ngenye indlela, zonke izivivinyo nezilinganiso zizokwenziwa ngaphansi kwalezi zimo zemvelo ezilandelayo:

Izinga lokushisa: 15℃~35℃;

Umswakama ohlobene: 25% ~ 75%;

Umfutho womoya: 86kPa~106kPa.

4.2 Hlola imibhalo yezobuchwepheshe efanele

(1) Qinisekisa ukuthi inani lemininingwane negama liyahambisana yini nefomu lokuhlola ukulethwa;

(2) Hlola ukuthi umkhiqizi ungumhlinzeki oqeqeshiwe yini.

4.3 Ukuhlolwa kokupakishwa

(1) Hlola ukuthi ingabe ibhokisi lokupakisha limakwe ngolwazi olulandelayo endaweni esobala: igama lomkhiqizi, igama lomkhiqizo, imodeli yomkhiqizo, usuku lokuhlolwa kanye nenani lokupakisha, nokuthi okuqukethwe okumakiwe kufiphele noma kuwile yini.

(2) Hlola ukuthi ibhokisi lokupakisha liphrintiwe noma linamathiselwe izimpawu zokuthutha njengokuthi "Phatha Ngokunakekela", "Ukwesaba Ukumanzi", "Phezulu", njll. endaweni esobala, nokuthi okuqukethwe kwezimpawu kufiphele noma ehlutshiwe.

(3) Hlola ukuthi ukupakishwa kwangaphakathi nangaphandle kwemikhiqizo ebhokisini kukhubazekile, konakele, kunomswakama noma kuyampintsha.

(4) Hlola ukuthi amadokhumenti asebhokisini lokupakisha aphelele yini. Okungenani kufanele kube nohlu lokupakisha, isitifiketi somkhiqizo, izesekeli kanye namanye amadokhumenti angahleliwe afanelekile.

4.4Ukuhlolwa kokubukeka nokuhlolwa kobukhulu

Indlela yokuhlola ebonakalayo isetshenziselwa ukuhlola isimo somkhiqizo, ikhwalithi yokucubungula kanye nekhwalithi yendawo, kanye nokulinganisa ubukhulu ukuze kuhlangatshezwane nezidingo ze-4.3. Kubandakanya kodwa kungagcini kulokhu okulandelayo:

(1) Ukuthi ukumaka (izimpawu zombhalo noma izimpawu zezithombe) ziyahambisana yini nezimfuneko zencazelo;

(2) Ilebula akumele libe namaphutha angafundeki (afiphalisiwe, ayachichima, awaphelele, anqanyuliwe);

(3) Kufanele ihlanzeke, ingabi nakungcola, ingabi nasici, futhi ingabi namonakalo owenziwe ngomshini;

(4) Ubukhulu kufanele buhlangabezane nemininingwane yobuchwepheshe nezidingo zokubekezelela.

4.5 Ukuhlolwa kukagesi

(1) Vula ukuhlolwa kwe-voltage yesifunda

(2) Ukuhlolwa kwamandla kagesi

(3) Ukuhlolwa kokusebenza kwe-Pulse

(4) Ukuhlolwa kokusebenza kwePassivation (kusebenza kumabhethri e-Li-SOCl2)

(5) Ukuhlolwa kwamandla okuqamba

4.6 Ukuhlolwa kokusebenza kwemishini

(1) Ukuhlolwa kwamandla etheminali (kusebenza ezinhlotsheni ezinamathebhu ensimbi)

(2) Ukuhlolwa komthelela

(3) Ukuhlolwa kokudlidliza

4.7 Ukuhlolwa kokusebenza kwe-Soldering

(1) Ukuhlolwa kokuthengiselana (kusebenza ezinhlotsheni ezinamathebhu e-solder yensimbi)

(2) Ukuhlolwa kokumelana nokushisa kwe-Welding (kusebenza ezinhlotsheni ezinamathebhu wensimbi wokushisela)

4.8 Ukuhlolwa kwemvelo

(1) Ukuhlolwa kokushaqeka okushisayo

(2) Ukuhlolwa kwezinga lokushisa eliphezulu nomswakama ophezulu

(3) Ukuhlolwa kwesifutho sikasawoti

Ngenxa yobuchwepheshe obuqinile bokuhlola ukuphepha, abahlinzeki kudingeka banikeze imibiko yokuhlola evela eceleni.

(1) Ukuhlolwa kokulingisa okuphezulu

(2) Ukuhlolwa kwesifunda esifushane sangaphandle

(3) Ukuhlolwa komthelela wento enzima

(4) Ukuhlolwa kwe-Extrusion

(5) Ukuhlolwa kokukhishwa okuphoqelelwe

(6) Ukuhlolwa kokushaja okungajwayelekile

(7) Ukuhlolwa kokuwa kwamahhala

(8) Ukuhlolwa kokuhlukunyezwa okushisayo

5.Imithetho yokuhlola

5.1 Ukuhlolwa kwefekthri

Iyunithi yokukhiqiza izohlola imboni yomkhiqizo ngamunye okhiqizwe ngezindlela zokuhlola ezinikezwe kuleli zinga lokuhlola. Ngemuva kokuphumelela ukuhlolwa, kuzokhishwa isitifiketi sekhwalithi. Ukuze uthole izinto zokuhlola, bheka isithasiselo.

5.2 Ukuhlolwa kwamasampula

Ukuhlolwa kwamasampula kuzokwenziwa ngokuhambisana nendlela yokusampula ecaciswe ku-GB/T2828.1 "Inqubo Yokuhlola Isampula Ingxenye 1 Uhlelo Lokuhlola Isampula Lokucushwa Kweqoqo Olutholwe Ngomkhawulo Wekhwalithi Yokwamukela (AQL)". Ngokwaleli zinga lokuhlola, izinto zokuhlola zihlukaniswe izigaba ezimbili: A no-B. Isigaba A siyinto ye-veto, futhi isigaba B asiyona into ye-veto. Uma kwenzeka noma yikuphi ukwehluleka Kwesigaba A kusampula, iqoqo lizokwahlulelwa njengelingafaneleki. Uma kwenzeka ukwehluleka kweSigaba B futhi ukuhlolwa kuphumelela ngemva kokulungiswa, iqoqo lizokwahlulelwa njengelifanelekile.

5.3 Ukuhlolwa kokuqinisekisa ngezikhathi ezithile

Amasampula okuqinisekisa okuvamile azokwenziwa ngokuhambisana ne- "Periodic Confirmation and Inspection System for Key Materials", futhi ukuhlolwa kuzokwenziwa ngokuhambisana nezinto zokuhlola, izidingo zokuhlola kanye nezindlela zokuhlola ezishiwo kuleli zinga lokuhlola ukuze kunqunywe ukuthotshelwa kokuhlolwa. izici zomkhiqizo nezinhlinzeko zaleli zinga lokuhlola.

Ngesikhathi sokuhlolwa kokuqinisekisa ngezikhathi ezithile, uma into eyodwa noma enye yesampula ihluleka, umkhiqizo uzobhekwa njengongafaneleki, futhi iyunithi yokukhiqiza izokwaziswa ukuze kuqinisekiswe ikhwalithi nokulungisa.

5.4 Ukuhlolwa kokusebenza okugcwele

Hlola ngokuya ngezinto zokuhlola, izidingo zokuhlolwa nezindlela zokuhlola ezishiwo kuleli zinga lokuhlola ukuze unqume ukuhambisana nezimpawu zomkhiqizo nezinhlinzeko zaleli zinga lokuhlola.

Ukuhlolwa kokusebenza okugcwele kulungele ukuhlolwa kwesampula yiyunithi yokukhiqiza. Ekuhlolweni kokusebenza okugcwele, uma enye noma enye into yesampula ihluleka, umkhiqizo uzobhekwa njengongafaneleki.

6 isitoreji

Imikhiqizo epakishwe kahle kufanele igcinwe endaweni yokugcina impahla enezinga lokushisa elingu-0°C kuya ku-40°C, umswakama ohlobene no-RH <70%, umfutho womoya womkhathi ongu-86kPa kuya ku-106kPa, umoya omncane futhi ongenawo amagesi abolayo.

Isithasiselo A: Ubukhulu bereferensi

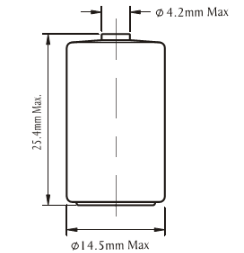

Ibhethri lewashi le-A.1 (14250)

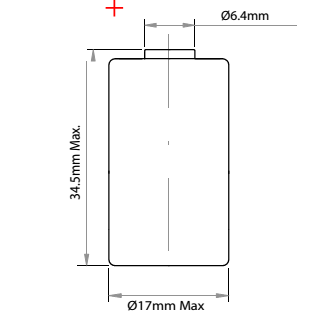

A.2 Ibhethri yokufunda imitha yokucisha ugesi (CR123A)

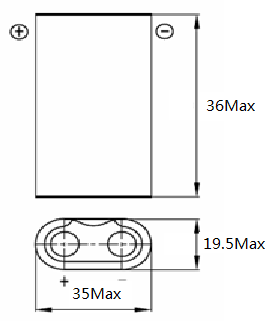

A.3 Ibhethri yokufunda imitha yokucisha ugesi (CR-P2)

Isikhathi sokuthumela: Nov-29-2023