Amazinga kazwelonke ayimpoqo kanye ne-IEC banawoizidingo zobuchwepheshengokumakwa, ukuvikela ukulwa nokushaqeka, ukwakheka, ukusebenza kukagesi, ukusebenza kwemishini, njll. kwamapulaki namasokhethi ezinjongo zasendlini nezinye ezifanayo. Okulandelayo yizindinganiso zokuhlola nezindlela zamapulaki namasokhethi.

1. Ukuhlolwa kokubukeka

2. Ukuhlolwa kwe-Dimensional

3. Ukuvikela ngokumelene nokushaqeka kukagesi

4. Izinyathelo zokubeka phansi

5. Amatheminali kanye nezihloko

6. Ukwakheka kwesokhethi

7. Akwazi ukumelana nokuguga kanye nobufakazi bomswakama

8. Ukumelana ne-insulation namandla kagesi

9. Izinga lokushisa liyakhuphuka

10. Ukuphula amandla

11. Ukusebenza okujwayelekile (ukuhlolwa kwempilo)

12. Amandla okukhipha

13. Amandla omshini

14. Ukuhlolwa kokumelana nokushisa

15. Izikulufu, izingxenye eziphethe okwamanje kanye nokuxhumana kwazo

16. Ibanga le-creepage, imvume kagesi, ibanga lokuvala lokungena lokungena

17. Ukumelana nokushisa okungavamile kanye nokumelana nomlilo wezinto zokushisa

18. Ukusebenza kwe-anti-rust

1. Ukuhlolwa kokubukeka

1.1 Izingxenye eziyinhloko zomkhiqizo kufanele zibe nalawa mamaki alandelayo:

-Ikalwe okwamanje (ama-amps)

- I-voltage elinganiselwe (volts)

- Uphawu lokuphakelwa kwamandla;

-Igama, uphawu lokuhweba noma umazisi womenzi noma umdayisi;

Inombolo yomkhiqizo

-Isitifiketi sophawu

1.2 Izimpawu ezifanele kufanele zisetshenziswe emkhiqizweni:

1.3 Kumasokhethi angashintshi, izimpawu ezilandelayo kufanele zimakwe ezingxenyeni eziyinhloko:

-Izilinganiso zamanje, i-voltage elinganiselwe kanye nezakhiwo zokuhlinzeka ngogesi;

-Igama noma uphawu lokuhweba noma uphawu lokuhlonza lomkhiqizi noma umdayisi;

-Ubude be-insulation okufanele bukhumulwe ngaphambi kokuthi umqhubi afakwe kutheminali engena-screwless (uma ikhona);

- Uma isokhethi ifaneleka kuphela ukuxhuma izintambo eziqinile, kufanele kube nesibonakaliso sokuthi i-screwless terminal ifaneleka kuphela ukuxhuma izintambo eziqinile;

Inombolo yemodeli, okungaba inombolo yekhathalogi.

1.4 Ikhwalithi yokubukeka: Ingaphezulu lesokhethi kufanele libe bushelelezi, igobolondo kufanele lifane, futhi akufanele kube nezimbotshana, imifantu, ama-indent, ama-bumps, umonakalo, amabala, noma ukungcola; izingxenye zensimbi akufanele zibe ne-oxidation, izindawo zokugqwala, ukuguqulwa, ukungcola, futhi ukugqoka kufanele kube okufanayo futhi kukhanye.

1.5 Ukupakisha: Igama lomkhiqizo, imininingwane ecacisiwe, ikhodi yezinto ezibonakalayo, igama lemboni, inani, nenombolo yeqoqo lokukhiqiza kufanele kumakwe ebhokisini lokupakisha.

2. Ukuhlolwa kwe-Dimensional

2.1 Isokhethi kufanele ifakwe futhi ikhishwe izikhathi ezingu-10 ngepulaki enosayizi omkhulu wephinikhodi ohlangabezana nezimfuneko zezinga elihambisanayo. Ubukhulu bephini bubhekwa ngokulinganisa noma kusetshenziswa igeji.

2.2 Kuhlelo olunikeziwe, ipulaki akufanele ihlangane nalezi zisekelo ezilandelayo:

-Amasokhethi anezilinganiso eziphezulu ze-voltage noma izilinganiso zamanje eziphansi;

-Amasokhethi anezinombolo ezahlukene zama-electrode;

3.Pukuzivikela ngokumelene nokushaqeka kukagesi

3.1 Uma ipulaki ifakwe ngokugcwele kusokhethi, izingxenye ezibukhoma zepulaki kufanele zingakwazi ukufinyeleleka. Hlola ukuthi ifanelekile yini ngokuhlolwa. Amasokhethi angaguquki, amapulaki ahlanganisiwe kanye nezindawo zokuphuma izisekelo eziphathwayo zizokwakhiwa futhi zakhiwe ngendlela yokuthi, lapho zifakiwe noma zifakwe izintambo ukuze zisetshenziswe ngendlela evamile, izingxenye ezibukhoma azifinyeleleki ngisho nangemva kokususwa kwalezo zingxenye ezifinyeleleka ngaphandle kwamathuluzi. Okufanayo kuya ezingxenyeni ezingasuswa.

3.2 Uma izesekeli zikagesi zinezintambo futhi zifakwe ngokwezidingo zokusetshenziswa okuvamile, ziseyizingxenye ezifinyeleleka kalula, ngaphandle kwezikulufu ezincane nezingxenye ezifanayo ezisetshenziselwa ukulungisa izingxenye eziyinhloko kanye namakhava namakhava amasokhethi, ahlukanisiwe kokuphilayo. izingxenye. Kufanele zenziwe ngezinto zokuvikela. impahla.

3.3 Noma iyiphi iphinikhodi yepulaki ngeke ikwazi ukuhlangana nesokhethi ephilayo yesokhethi lapho enye iphinikhodi isesimweni sokufinyeleleka.

3.4 Izingxenye zangaphandle zepulaki kufanele zenziwe ngezinto ezivikelayo. Lokhu akubandakanyi izingxenye ezifinyeleleka kalula njengezikulufu zokuhlanganisa, izikhonkwane eziphethe manje, izikhonkwane eziphansi, izinsimbi eziphansi, namaringi ensimbi azungeze izikhonkwane.

3.5 Isokhethi enomnyango ovikelayo, lapho ipulaki ikhishwa, isokhethi ephilayo ingavikelwa ngokuzenzakalelayo.

3.6 Umkhono ophansi wesokhethi akufanele ukhubazeke ngendlela ebeka ukuphepha engozini ngenxa yokufakwa kwepulaki.

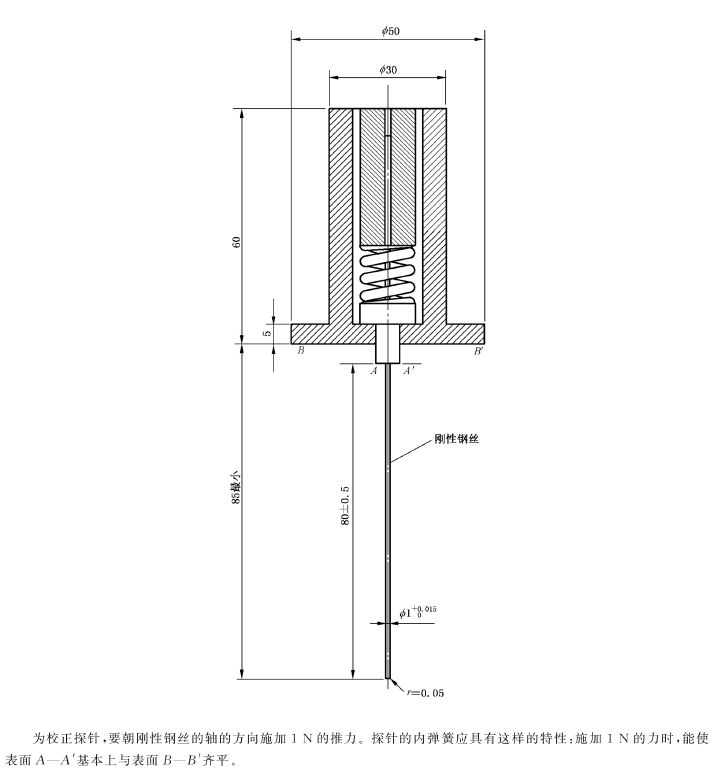

3.7 Kumasokhethi anokuvikela okuthuthukisiwe, uma efakiwe futhi efakwe izintambo ngokuya ngezidingo zokusetshenziswa okuvamile, izingxenye ezibukhoma kufanele zingafinyeleleki ngophenyo oluwububanzi obungu-1 mm. Njengoba kuboniswe ngezansi:

4. Izinyathelo zokubeka phansi

4.1 Uma ipulaki ifakiwe, iphinikhodi eliphansi kufanele lixhunywe kusokhethi eliphansi kuqala, bese iphini eliphethe manje linikezwe amandla. Lapho ipulaki ikhishwa, iphinikhodi ephethe manje kufanele inqamuke ngaphambi kokuba iphini eliphansi linqamuke.

4.2 - Usayizi wetheminali yaphansi uzofana nosayizi wetheminali yekhondatha yamandla ohambisanayo.

- Itheminali yomhlaba yezinsiza zikagesi ezibuyiselekayo nezithinta umhlaba kufanele ibe ngaphakathi.

- Itheminali yomhlaba ye-socket-outlet engaguquki kufanele igxilwe esisekelweni noma engxenyeni egxilwe ngokuqinile esisekelweni.

- Umkhono ophansi we-outlet yesokhethi engashintshi kufanele unamathele esisekelweni noma kukhava. Uma kugxilwe kukhava, umkhono waphansi uzoxhumeka ngokuzenzakalelayo nangokuthembekile kutheminali ephansi lapho ikhava isendaweni yayo evamile. Othintana nabo kufanele babe ne-silver plated noma babe nokugqwala futhi bangagqoki okungaphansi kwe-silver plated.

4.3 Kumasokhethi angashintshi anamasokhethi aphansi, izingxenye zensimbi ezifinyeleleka kalula ezizoba bukhoma lapho ukufakwa kwe-insulation kwehluleka kufanele zixhunywe unomphela futhi ngokuvikelekile kutheminali ephansi.

4.4 I-socket-outlet enekhodi ye-IP ephakeme kune-IPXO kanye nendawo evalekile enekhebula yokungena engaphezu kweyodwa izofakwa amatheminali angaphansi agxilwe Ngaphakathi, noma inikeze isikhala esanele samatheminali antantayo, ivumele ukuxhumana okungenayo nokuphumayo ukuze kuqinisekiswe ukuqhubeka umhlabathi wesifunda.

4.5 Uxhumano phakathi kwetheminali yaphansi kanye nezingxenye zensimbi ezifinyeleleka kalula kufanele kube uxhumano olumelana kancane, futhi ukumelana akufanele kube kukhulu kuno-0.05Ω.

4.6 Amasokhethi angaguquki ahloselwe ukuhlinzeka isekethe evikeleke ekuphazanyisweni kukagesi lapho okokusebenza ezixhunywe kuzo kufanele kufakwe isokhethi ephansi futhi amatheminali ayo azohlukaniswa ngogesi kunoma iyiphi into efakwa insimbi noma umhlaba ovikelayo okungenzeka exhunywe ohlelweni. ehlukaniswe ngogesi kwezinye izingxenye eziveziwe zesekethe.

5.Amatheminali namaheda

5.1 Amasokhethi angashintshile abuyiselekayo kufanele afakwe amatheminali anezikulufu noma amatheminali angenazikulufu.

5.2 Amapulaki axhumekeka kabusha kanye namasokhethi aphathekayo aphathekayo kufanele afakwe amatheminali ane-clamping enentambo.

5.3 Uma izintambo ezidayiswe ngaphambili zisetshenziswa, kufanele kuqashelwe ukuthi kumatheminali ohlobo lwesikulufu, indawo edayisiwe kufanele ibe ngaphandle kwendawo yokubopha lapho ixhunywe ekusetshenzisweni okuvamile.

5.4 Nakuba izingxenye ezisetshenziselwa ukubopha amakhondatha kutheminali zingasetshenziswa ukugcina itheminali isesimweni esivamile noma ukuvimbela itheminali ukuthi ingazungezi, akumele zisetshenziselwe ukulungisa noma yiziphi ezinye izingxenye.

5.3 Itheminali yohlobo lwe-thread clamp

-Amatheminali okubopha anemicu kufanele akwazi ukuxhuma amakhondaktha angalashiwe;

- Amatheminali okubopha imicu kufanele abe namandla anele okusebenza futhi akufanele enziwe ngensimbi ethambile noma insimbi ejwayele ukukhasa;

- Amatheminali okubamba imicu kufanele amelane nokugqwala; amatheminali e-thread clamping akufanele alimaze ngokweqile ama-conductor lapho ewacindezela;

-Amatheminali okubamba anemicu angaqinisa ikhondukta phakathi kwezindawo ezimbili zensimbi;

-Itheminali yokubopha intambo, lapho uqinisa isikulufu noma nati, akunakwenzeka ukuthi izintambo zekhondatha eqinile ye-single-core noma i-conductor eboshiwe ziphume;

-Amatheminali ohlobo lwe-thread clamp azolungiswa kupulaki nesokhethi ngendlela yokuthi izikulufu zokubopha noma amantongomane zingakwazi ukuqiniswa noma ukuxegiswa ngaphandle kokubangela ukuthi itheminali ixege.

- Izikulufu zokubopha namantongomane amatheminali aphansi ohlobo lwe-thread-clamp kufanele zikhiyeke ngokwanele ukuze kugwenywe ukuxega ngephutha; futhi kufanele ingabi namathuluzi.

-Amatheminali omhlaba ohlobo lwe-thread clamp azoba ngendlela yokuthi kungabikho ubungozi bokugqwala okuvela ngokuthintana phakathi kwalezi zingxenye kanye ne-conductor yethusi yomhlabathi noma ezinye izinsimbi ezithintana nayo.

5.4 Amatheminali angenasikulufu amakhondaktha ekhopha angaphandle

- Amatheminali angenasikulufa angaba wuhlobo olufanele kuphela amakhondatha ekhopha eliqinile, noma abe uhlobo olufanele kokubili amakhondakta wethusi aqinile nathambile.

- Amatheminali angenasikulufa azokwazi ukuxhuma amakhondatha angalungiswanga ngokukhethekile.

-Amatheminali angenantambo kufanele avikelwe kahle kusokhethi. Amatheminali angenasikulufa akufanele axege ngenxa yoxhumo noma ukunqanyulwa kwamakhondatha ngesikhathi sokufakwa.

-Amatheminali angenantambo azokwazi ukumelana nezingcindezi zemishini ezenzeka ngesikhathi sokusetshenziswa okuvamile.

-Amatheminali angenantambo azokwazi ukumelana nezingcindezi zikagesi kanye nezishisayo ezenzeka ngesikhathi sokusetshenziswa okuvamile.

6.1 Izingxenye zomkhono wesokhethi kufanele zinwebeke ngokwanele ukuze kuqinisekiswe ingcindezi eyanele yokuxhumana ngokumelene nezikhonkwane zepulaki.

6.2 Izingxenye ze-socket-outlet ezihlangene ezithinta izikhonkwane zepulaki futhi ezisetshenziselwa ukuxhuma ugesi lapho ipulaki ifakwe ngokugcwele kusokhethi kufanele ziqinisekise ukuthi kukhona ukuxhumana kwensimbi okungenani emaceleni amabili aphikisanayo ngayinye. phini.

6.3 Umkhono wesokhethi kufanele umelane nokugqwala nokuguga.

6.4 Izidingo zamalayini afaka ama-insulating kanye nezithiyo zokuvikela ukushisa.

6.5 I-socket-outlet izokwakhiwa ukuze kube lula ukufakwa kwamakhondakta kanye nokuxhuma kahle kumatheminali, ukuma kahle kwamakhondatha, ukuvikeleka kalula kwezingxenye ezinkulu odongeni noma ebhokisini, kanye nesikhala esanele.

6.6 Idizayini ye-socket-outlet akufanele ivimbele ukuhlangana okugcwele nepulaki efanele ngenxa yanoma yikuphi ukuvela endaweni yokukhwelana. Lapho ipulaki ishuthekwa kusokhethi, kunqunywa ngesilinganiso ukuthi igebe phakathi kwendawo yokukhwelana yepulaki nendawo yokuhlangana yesokhethi akufanele lidlule u-1mm.

6.7 Iphinikhodi eliphansi kufanele libe namandla anele okusebenza.

6.8 Isokhethi ephansi, isokhethi yesigaba kanye nesokhethi engathathi hlangothi kufanele ikhiyelwe ukuvimbela ukuzungezisa.

6.9 Imichilo yensimbi yesekhethi yaphansi akufanele ibe namabhula angalimaza ukufakwa kwamakhondatha amandla.

6.10 Amasokhethi afakwe emabhokisini okufaka azoklanywa ukuze iziphetho zekhondakta zikwazi ukucutshungulwa ngemva kokuba ibhokisi lokufaka lifakwe endaweni evamile kodwa ngaphambi kokuba isokhethi lifakwe ebhokisini lokufaka.

6.11 Iminyango yekhebula kufanele ivumele ukungena kwamapayipi ekhebula noma amashethi ukuze kunikeze ukuvikeleka okuphelele kwemishini kwezintambo.

7. Imelana nokuguga futhi ivikela umswakama

7.1 Isokhethi kufanele ibe nokumelana nokuguga: ngemva kokuba isampula ivezwe kuhhavini wezinga lokushisa elingu-70℃±2℃ amahora angu-168, isampula akufanele libe nemifantu futhi okokusebenza kwayo akufanele kunamathele noma kushelele.

7.2 Isokhethi kufanele ivikele umswakama: ngemva kokuba isampula ligcinwe amahora angu-48 kumswakama ohlobene ongu-91%~95% kanye nezinga lokushisa elingu-40℃±2℃, ukumelana nokufakwa kwe-insulation namandla kagesi kufanele kuhambisane nemithethonqubo.

8. Ukumelana ne-insulation namandla kagesi

8.1 Ukumelana ne-insulation phakathi kwazo zonke izigxobo ezixhunywe ndawonye nomzimba ≥5MΩ.

8.2 Ukumelana nokufakwa phakathi kwazo zonke izigxobo kungu-≥2MΩ.

8.3 Faka isivivinyo sokumelana ne-voltage engu-50Hz, 2KV~ phakathi kwazo zonke izingxenye umzuzu owodwa. Akufanele kube nokucwayiza noma ukuwohloka.

9. Izinga lokushisa liyakhuphuka

Ngemva kokuba isampula isiphumelele ukuhlolwa kokuphila, ukukhuphuka kwezinga lokushisa kwamatheminali alo akufanele kudlule ku-45K, izinga lokushisa eliphakeme kakhulu lezingxenye zensimbi ezifinyelelekayo akufanele lidlule ku-30K, futhi izinga lokushisa lezingxenye ezingezona ezensimbi ezifinyelelekayo akufanele lidlule ku-40K.

10. Ukuphula amandla

Ezisekelini zikagesi ezine-voltage elinganiselwe engekho ngaphezu kuka-250 V kanye namandla amanje akalwe angaphezu kuka-16 A, ukushaywa kwempahla yokuhlola kufanele kube phakathi kuka-50 mm no-60 mm.

Faka ipulaki phakathi nokuphuma kusokhethi izikhathi ezingu-50 (imivimbo engu-100), izinga le-plug-in nokukhipha lithi:

- Okwezinsiza zikagesi ezinezinga elilinganiselwe elingekho ngaphezu kuka-16 A kanye ne-voltage elinganiselwe engekho ngaphezu kuka-250V, imivimbo engu-30 ngomzuzu;

-Kwezinye izesekeli zikagesi, imivimbo engu-15 ngomzuzu.

Ngesikhathi sokuhlolwa, akufanele kwenzeke i-arc flash eqhubekayo. Ngemuva kokuhlolwa, isifanekiso ngeke sikhululeke emonakalweni ongaphazamisa ukusetshenziswa okuqhubekayo, futhi imbobo yokufaka iphini izokhululeka ekulimaleni okungathinta ukuphepha kwayo ngaphakathi kwencazelo yale dokhumenti.

11. Ukusebenza okuvamile (ukuhlolwa kwempilo)

Izesekeli zikagesi kufanele zikwazi ukumelana nezingcindezi zemishini, zikagesi nezokushisa ezivela ekusebenziseni okuvamile ngaphandle kokuguga okungadingekile noma eminye imiphumela eyingozi. Kusekhethi ene-voltage elinganiselwe, ekalwe okwamanje, i-COSφ=0.8±0.05, ipulaki futhi ukhiphe izikhathi ezingu-5000.

Ngesikhathi sokuhlolwa, akufanele kwenzeke i-arc flash eqhubekayo. Ngemuva kokuhlolwa, isifanekiso akufanele sibonise: ukugqokwa okungathinta ukusetshenziswa kwesikhathi esizayo; ukuwohloka kwezindlu, insulating gaskets noma izithiyo, njll; ukulimala kwesokhethi okungathinta ukusebenza okuvamile kwepulaki; ukuxhumeka okuxekethile kagesi noma kwemishini; ukuvuza kwe-sealant. ukuvuza.

12. Amandla okukhipha

Isokhethi kufanele iqinisekise ukuthi ipulaki kulula ukulifaka nokulikhipha futhi livimbele ipulaki ukuthi lingaphumi kusokhethi ngesikhathi sokusetshenziswa okuvamile.

13. Amandla omshini

Izesekeli zikagesi, amabhokisi okufaka abekwe phezulu, izindlala ezinentambo namakhava kufanele abe namandla anele okusebenza ukuze amelane nokucindezeleka komshini okukhiqizwa phakathi nokufakwa nokusebenzisa.

14.Ukuhlolwa kokumelana nokushisa

14.1 Isampula ishisiswe kuhhavini lokushisa elingu-100°C ± 2°C ihora elingu-1. Ngesikhathi sokuhlolwa, isampula akufanele senziwe izinguquko ezingathinta ukusetshenziswa kwesikhathi esizayo, futhi uma kune-sealant, akufanele igeleze ukuze iveze izingxenye ezibukhoma. Ngemva kokuhlolwa, uphawu kufanele lusafundeka.

14.2 Ngemva kokuhlolwa kokucindezela kwebhola, ububanzi bokuhlehlisa akumele budlule ku-2mm.

15.Izikulufu, izingxenye eziphethe njengamanje kanye nokuxhumana kwazo

15.1 Kokubili ukuxhumana kukagesi nokomshini kufanele kumelane nezingcindezi zemishini ezenzeka ekusetshenzisweni okuvamile.

15.2 Ngezikulufu ezibandakanya izintambo zezinto ezivikelayo nezikulufu okudingeka ziqiniswe lapho kuxhunywa izisekeli zikagesi phakathi nokufakwa, qinisekisa ukuthi ziqondiswe ngendlela efanele ezimbotsheni zezikulufu noma amantongomane.

15.3 Ukuxhunywa kukagesi kufanele kube ngendlela yokuthi ingcindezi yokuxhumana ingadluliswa ngempahla yokugquma.

15.4 Izikulufu nama-rivets kufanele zikhiywe lapho kuhlanganiswa ugesi kanye nokuxhunywa kwemishini ukuze kuvinjelwe ukuxega nokuphenduka.

15.5 Izingxenye eziphethe insimbi kufanele zenziwe ngensimbi ehlangabezana nezidingo zamandla emishini, ukuqhutshwa kukagesi kanye nezakhiwo zokugqwala.

15.6 Oxhumana nabo abazoshelela ngesikhathi sokusetshenziswa okuvamile kufanele benziwe ngensimbi engagqwali.

15.7 Izikulufu ezizithintayo nezizisikayo akufanele zisetshenziswe ukuxhuma izingxenye eziphethe manje. Angase asetshenziselwe ukuxhumana komhlaba, inqobo nje uma kusetshenziswa okungenani izikulufu ezimbili.

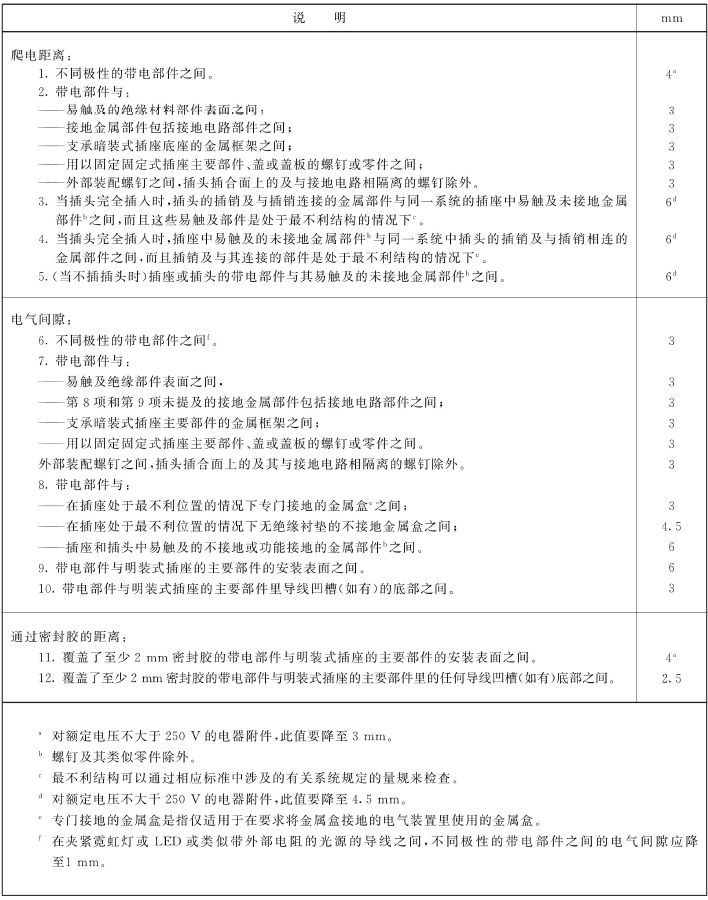

Ibanga 16

Ibanga le-creepage, imvume kagesi kanye nebanga nge-sealant imi kanje:

I-17.Ukushisa okungavamile nokumelana nomlilo wezinto zokuvikela

17.1 Ukuhlolwa kocingo olukhanyayo (kuvivinywe ngokuhambisana nemishwana 4 kuye ku-10 ye-BS6458-2.1:1984) Izinto ezivikelayo zezingxenye eziphethe amandla amanje kanye nezingxenye zesekethe ezisekelwe phansi 850 ℃

17.2 Izinto ezivikelayo zezingxenye ezingaguquki zamanje ezithwalayo kanye nezingxenye zesekethe ezisekelwe phansi 650℃.

17.3 Ngemva kokuhlolwa, alikho ilangabi elibonakalayo futhi akukho ukukhanya okuqhubekayo, noma ilangabi liyacisha noma kulahleka ukukhanya phakathi nemizuzwana engama-30 ngemva kokukhishwa kwentambo ekhanyayo; i-tissue paper ayibasi, futhi ibhodi likaphayini alishi.

18. Ukusebenza okungahambisani nokugqwala

Izingxenye zensimbi akufanele zibonise ukugqwala ngemva kokuphumelela ukuhlolwa kokugqwala.

Isikhathi sokuthumela: Feb-05-2024